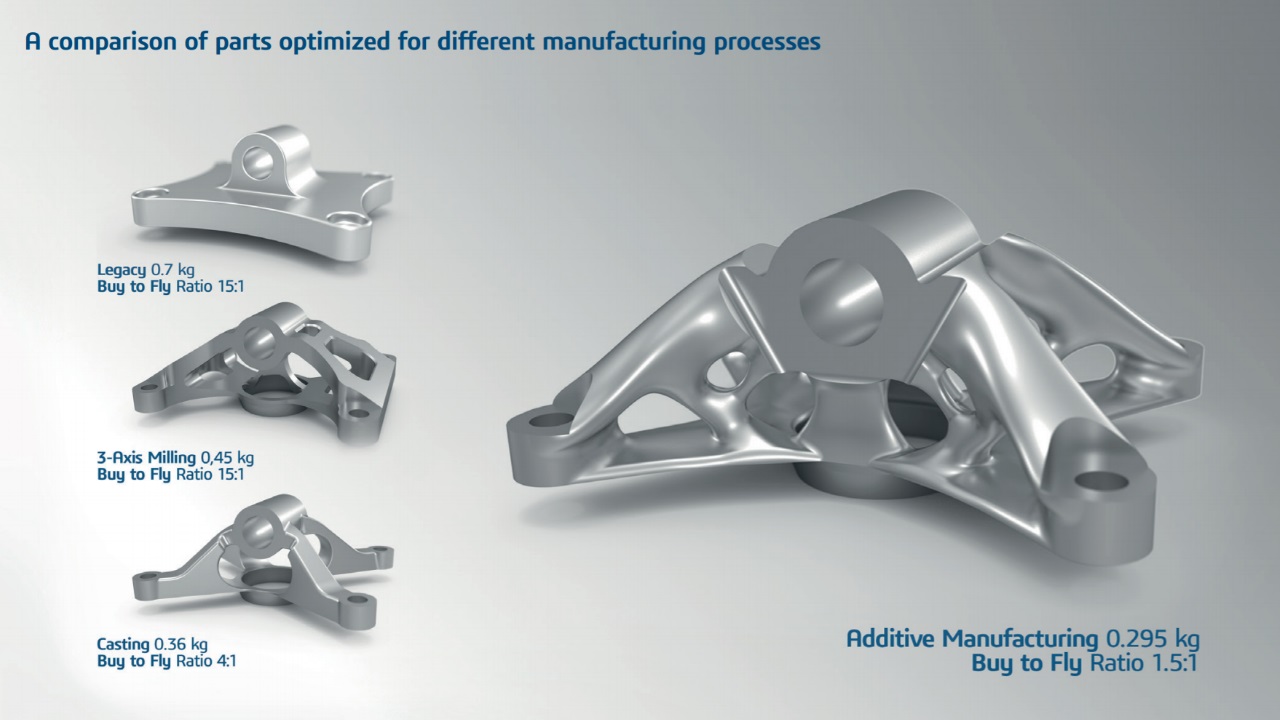

Design engineers constantly strive to minimize part weight, maximize stiffness, reduce cost and optimize material usage.

Today it is often cost-prohibitive to explore optimized parts. It can be difficult to collaborate across disciplines due to different systems and tools, delays and errors in data translation.

Optimization has traditionally required experts and has not been available to designers.

In this white paper we explore how innovative approaches to democratizing this technology in the hands of generalist engineers will transform mind-sets and processes, empowering designs without limits within the new (Generative) Design Revolution.

Example from whitepaper Design Revolution (2019)

photo: Design Revolution Whitepaper, 2019

Democratisation of R&D

izvodi iz dokumenta slobodnog za preuzimanje

"“We no longer talk about CAD as ‘Computer Aided Design’, but CAD for ‘Cognitive Augmented Design’. What does it mean? It means that science augments the capacity of the human being to create innovative designs. It empowers rather than replaces the engineer.” — Daniel Pyzak, Director, CATIA Engineering Centre of Excellence EMEAR

“Traditional approaches involve going back and forth between multiple solutions. It is very time consuming and painful to reconstruct optimized parts, and doesn’t allow for downstream design changes. There is no standardization, no talking to each other. It is an error-prone, non- repeatable process.” — Rani Richardson, Technical Director, Additive Manufacturing and Composites, Dassault Systèmes

“We no longer start from a blank sheet of paper. We start from the design space, and then you add some specifications, boundary conditions and forces. Concepts are then automatically generated and can be explored and examined to achieve the best possible result. This is the Generative Design approach.” — Daniel Pyzak, Director, CATIA Engineering Centre of Excellence EMEAR

NIAR (National Institute for Aviation Research) at Wichita State University (WSU) opened an innovation centre in order to use new technologies, such as parts produced using additive manufacturing for aeronautical industry applications. In 40 hours they were able to re-engineer a complete assembly and reduce weight by 15%.

(Generative) Design Revolution