DCAMCUT by Tebis

Programiranje erozimata sa žicom

Upoznajte funkcionalnosti vodećeg softverskog rešenja za obradu erozimatom sa žicom.

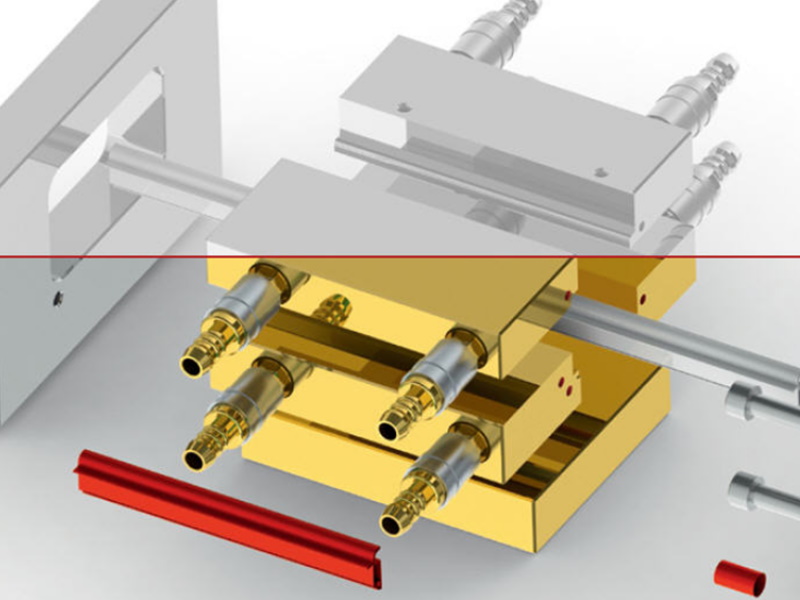

Radite erozimatom sa žicom? SolidCAM i Solfins vam obezbeđuju najprestižnije softversko rešenje proizvođača Tebis - DCAMCUT.

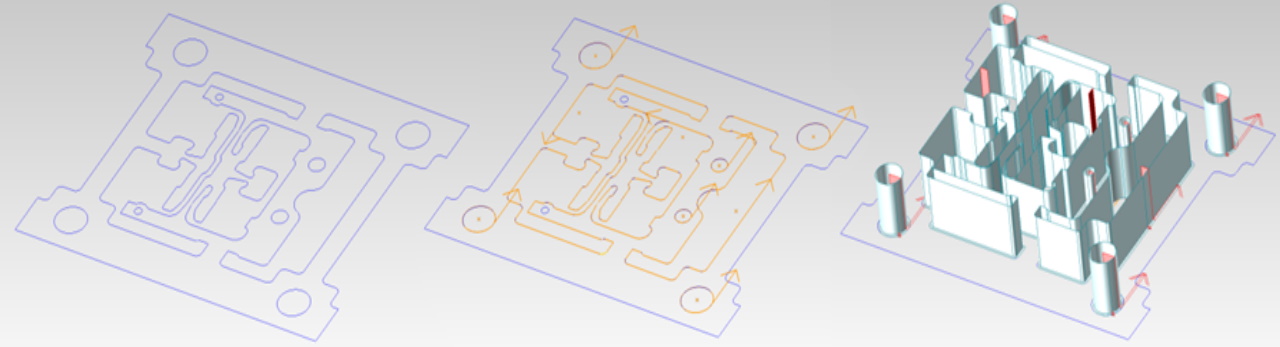

DCAMCUT runs totaly surfacebased

Never more creating intersections or creating projections of edgecurves

Never more extending surfaces by hand

Never more creating synchronization lines

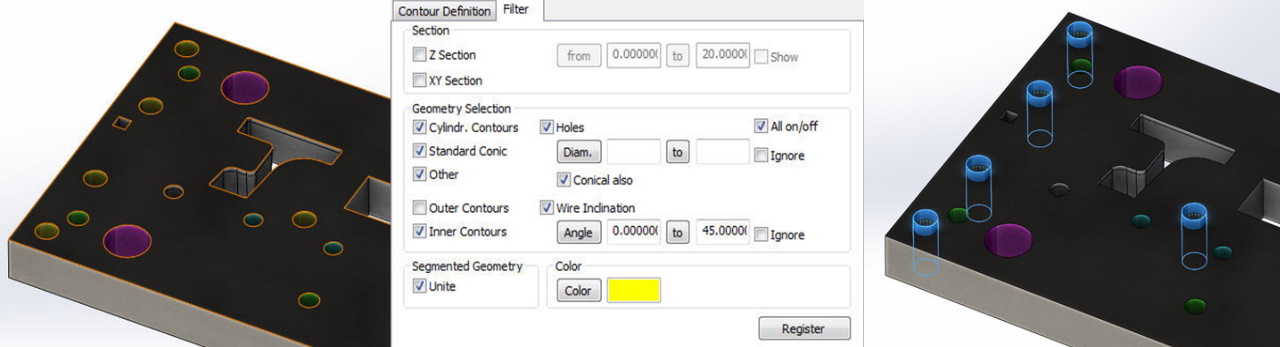

Semi - and fully automatic feature recognition for erodible contours

With the feature – recognition, contours can be preselected. Whether by color or shape, the feature recognition assists you throughout the contour defining process. Thus, DCAMCUT only generates what is needed.

Templates speed up your process

All machining operations can be stored, cataloged and reused at any time.

The programming effort is reduced considerably and minimizes manual errors.

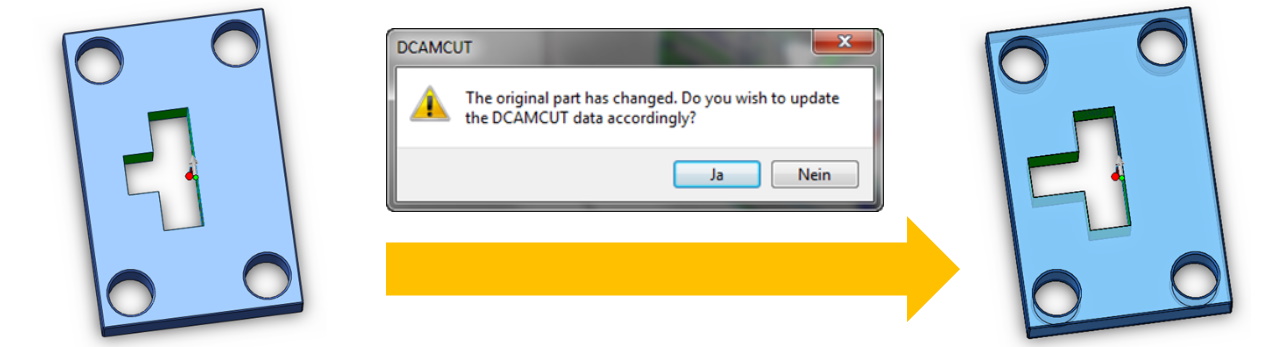

Always up to date with model-associative EDM-Technology

DCAMCUT detects model-changes fully or semi-automatically and calculates the new tool-path.

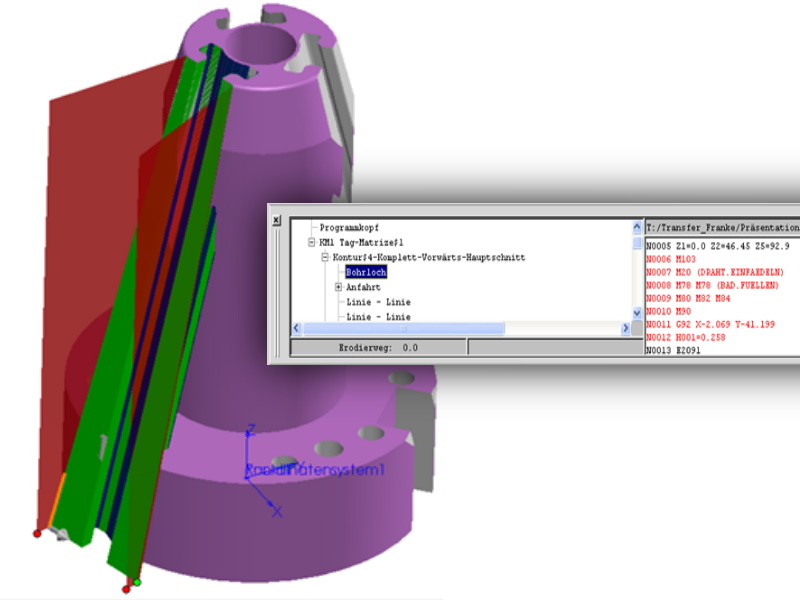

Important things allways in the focus

The integrated NC-Browser displays next to the sequential scheduling each tool-path graphically and marks the corresponding machine code in the NC program simultaneously. The process-reliability increases "visible".

Highly optimized roughing-cycles

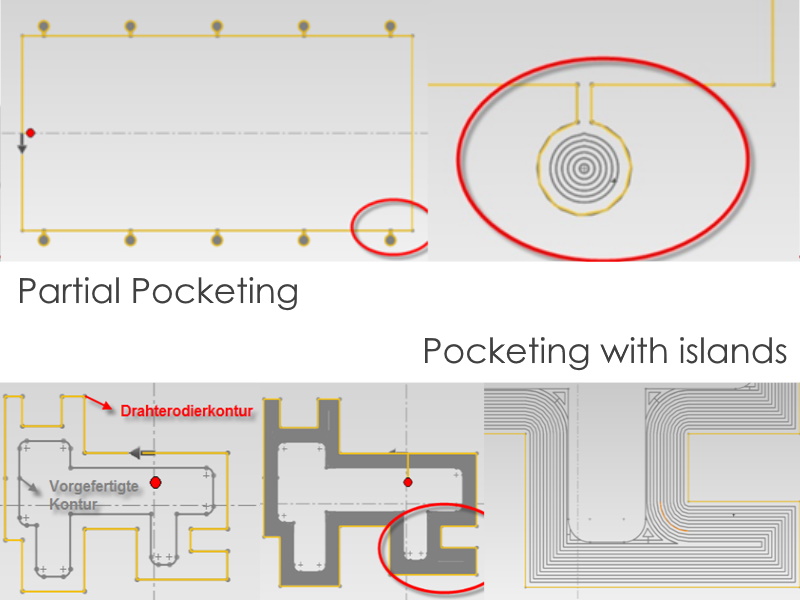

Obrada džepova

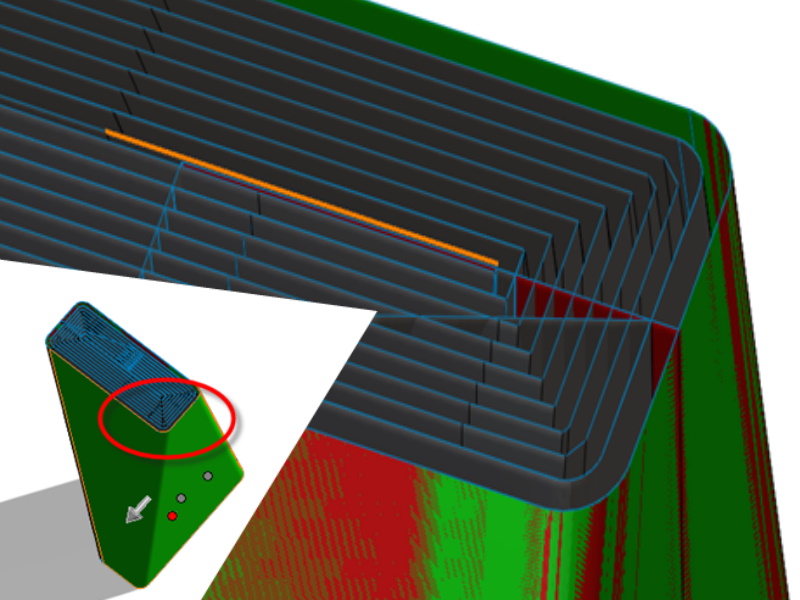

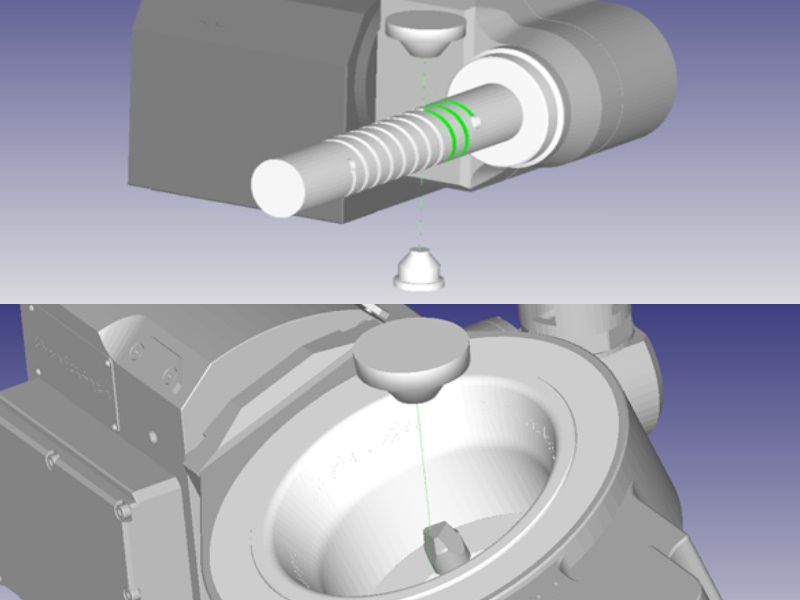

4-Axis roughing-cycle

The 4-axis roughing-cycle saves time and money. While in the past, employees were forced to remove the remaining material during weekends or at night, these steps can be saved by the 4-axis roughing-cycle.

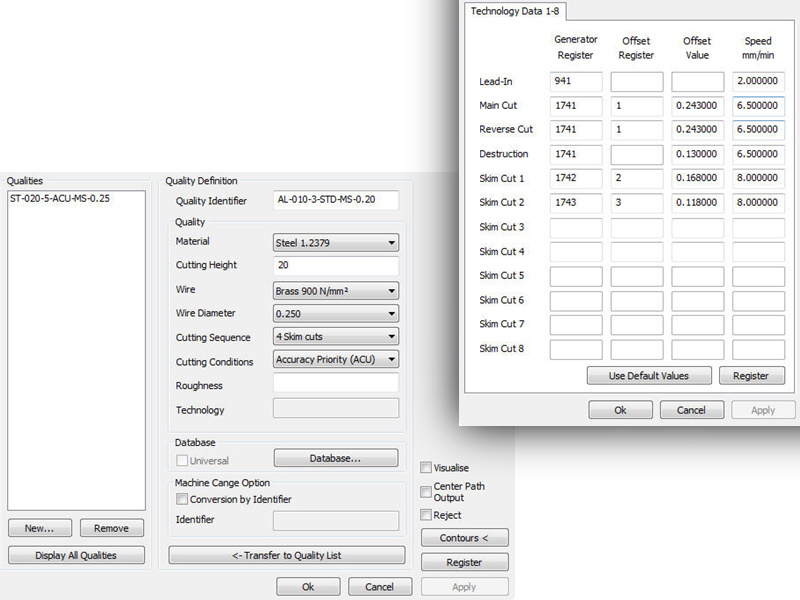

Professional technology - connectivity

Fully integrated technology database of all machine models provides close control programming . Additional work on the machine and resulting downtime can be avoided.

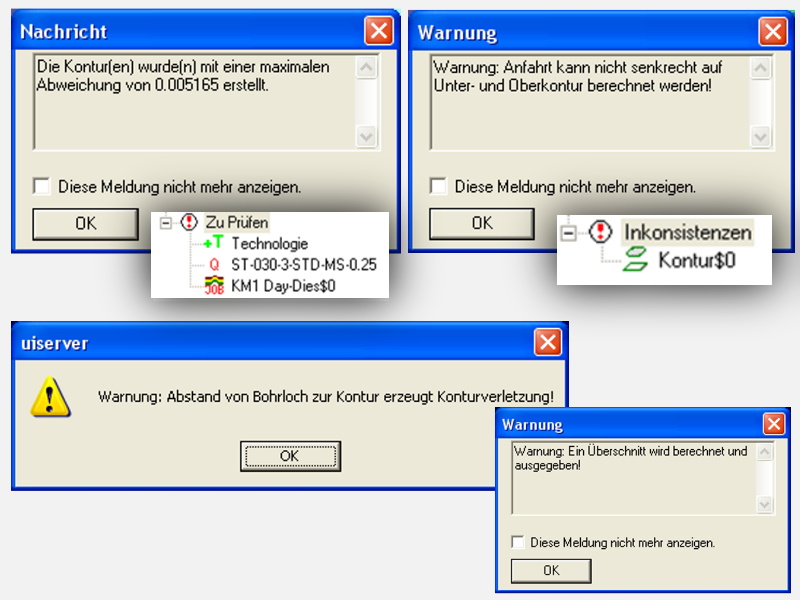

Detect inconsistencies in time

A variety of automatic tests secures the process during programming and assign the user through instructions and warnings on inconsistencies in time. Manual NC-Code manipulations on the machine-control is eliminated.

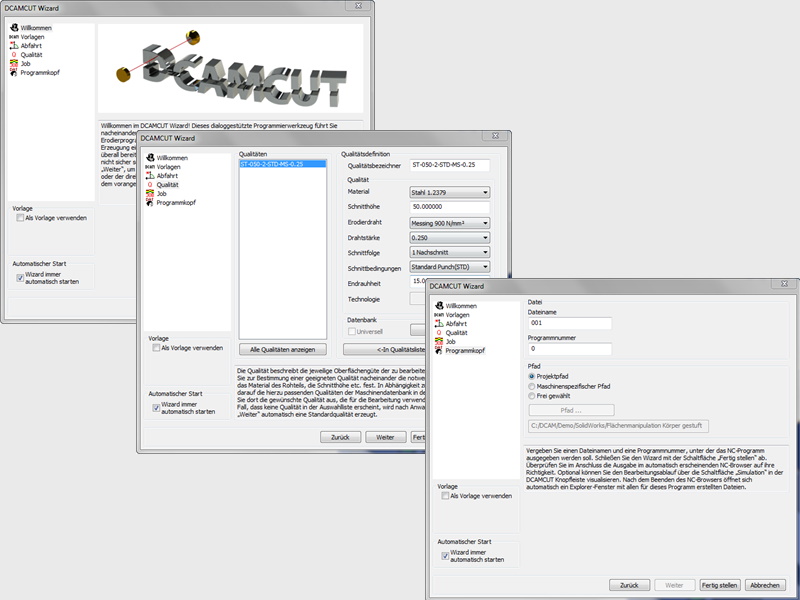

Get started easy with the Wizard

This dialog-based programming tool guides the user sequentially through all the steps, necessary to produce an executable NC-code. The required parameters and values are reduced to a minimum.

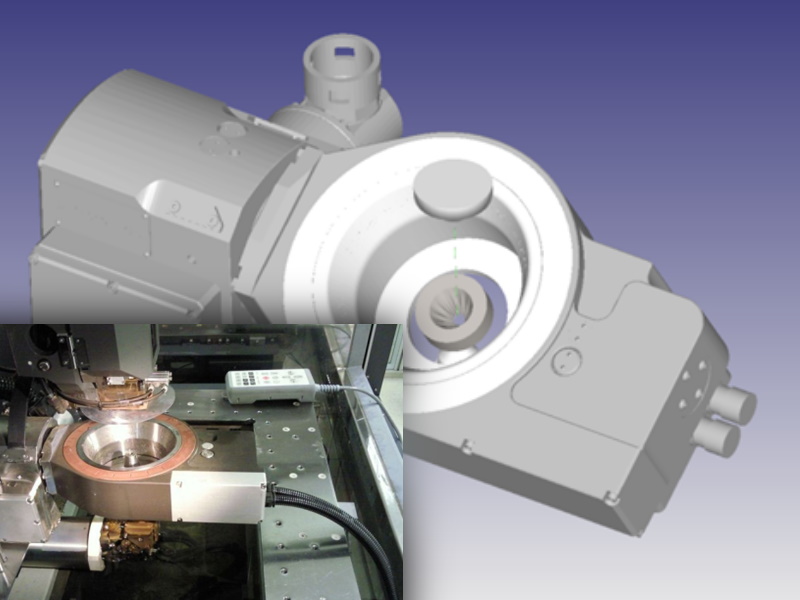

Multiaxis – Wire - EDM…

…multiplane EDM or simultaneously EDM

3D - Simulation

The tasks in CAM - Programming are becoming increasingly complex.

Especially dealing with the secondary axes carries a high degree of potential for collision. With the 3D – Simulation of DCAMCUT you have any movement perfectly under control. Collisions can be eliminated in advance!

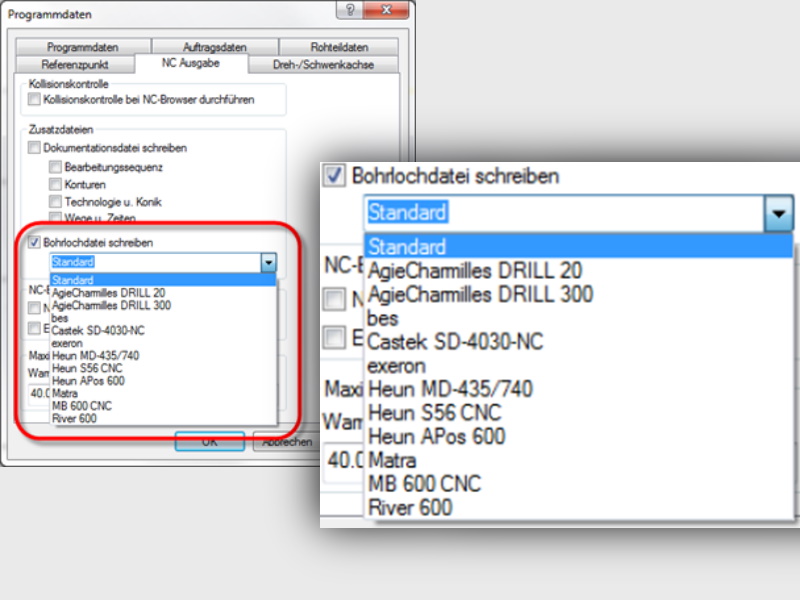

Starthole - Output via NC-Processor

From now, NC programs can be created for all common start hole drilling machines. DCAMCUT supports machines up to 5 - Axis

Integracija sa SolidWorks softverom

In addition to the standard, open interfaces, DCAMCUT includes a variety of direct CAD interfaces. Thus, the import of native data can offer many advantages in the further process.

-

DWG (*.dwg)

-

DXF (*.dxf)

-

IGES (*.igs;*iges)

-

STEP AP203/214(*.step;*.stp)

-

ACIS (*.sat)

-

Inventor Part (*.ipt)

-

Inventor Assembly (*.asm;*.asm.*;*.xas)

-

Parasolid (*.x_t;*.x_b;*.xmt_txt;*.xmt_bin)

-

ProE Part (*.prt;*.prt.*;*.xpr)

-

ProE Assembly (*.asm;*.asm.*;*.xas)

-

Rhino (*.3dm)

-

Solid Edge Part (*.par:*.psm)

-

Solid Edge Assembly (*.asm)

-

SolidWorks (*.prt;*.sldprt;*.asm;*.sldasm;*.drw;*.slddrw)

-

Unigraphics (*.prt)

-

VDAFS (*.vda)

-

VRML (*.wrl)

-

STL (*.stl)

-

Adobe Photoshop Files (*.psd)

-

Adobe Illustrator Files (*.ai)

-

CADKEY (*.prt;*.bdf;*.idb)

-

CATIA Graphics (*.cgr)

DCAMCUT Paketi

DCAMCUT Standard

osnovne funkcionalnosti za sve erozimate

- 2D contour - 2D contour definition on CAD sketch basis

- 2-level contour - rough surface machining via existing upper & lower contour and synchronization lines (sketches)

- 2-axis clearing standard - standard 2-axis clearing

- Standard simulation - standard simulation including calculation & visualization of the offset areas for all sections

- Solid simulation - material removal simulation for 3D visualization including demolding analysis

- Parametric - associativity of existing erosion jobs to model changes (automatic recalculation on volume, area models and sketches)

- 4-axis contour definition - 3D contour definition directly on volume and surface models

DCAMCUT Professional

sve iz Standard paketa +

- Feature recognition - automatic recognition & generation of erodible contours on volume & area models incl. filter functions

- Template technology - creation and cataloging of contour, job & program templates

- NC browser - NC browser technology including graphics feedback

DCAMCUT Expert

Sve iz Professional paketa +

- Partial clearing - 2-axis partial clearing

- Clearing with islands & above target allowance - 2-axis clearing with predefined islands & above target allowance

- 4-axis clearing - 4-axis clearing, 4-axis clearing with islands & 4-axis partial clearing

- Space curve - space curve processing for 3D curves

- Approximation for reverse-engineering a sequence of line elements within a user-definable tolerance in arcs, circles & lines (optional CAD output)

Želite da saznate više o ovom softveru? Pogledajte na Solfins blogu: Prvi koraci u DCAMCUT softverskom rešenju za upravljanje CNC erozimatima >