SolidCAM Turning

Programiranje CNC strugova

Spoljašnje/Unutrašnje struganje, obrada žljebova, narezivanje spoljašnjih/unutrašnjih navoja, bušenje, odsecanje.

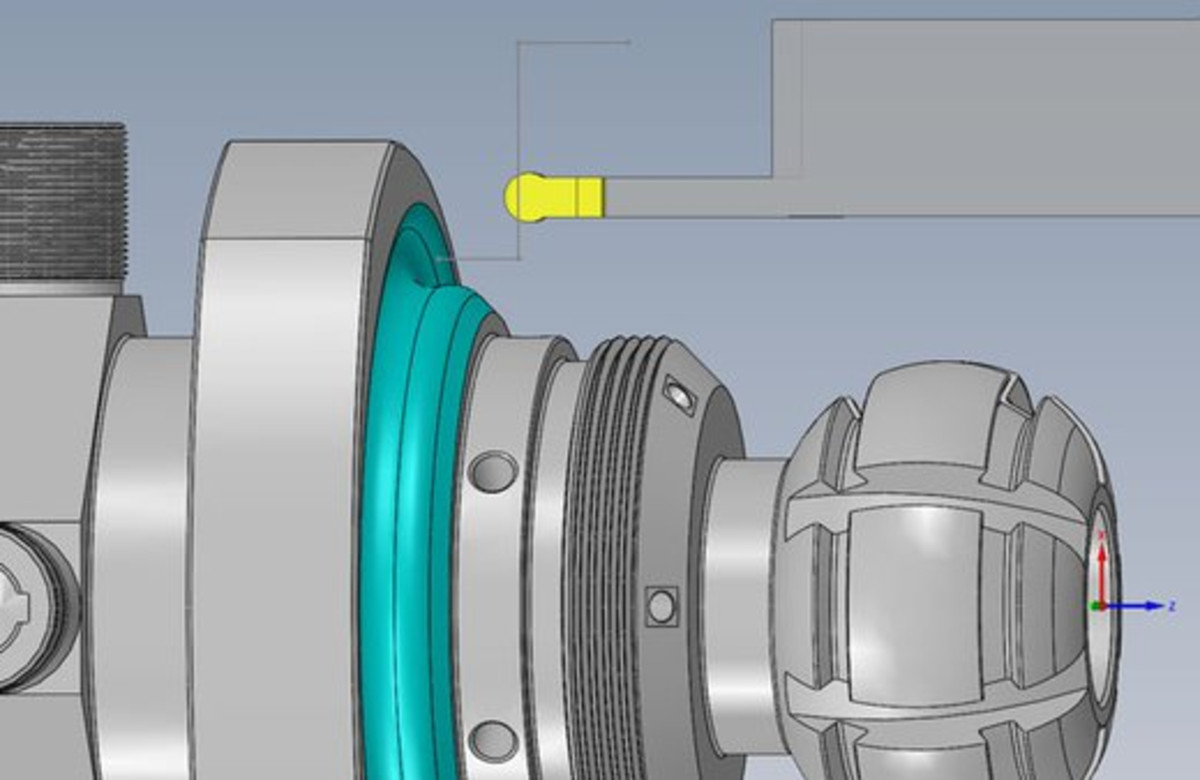

SolidCAM struganje i glodanje

SolidCAM pruža kompletan softverski paket za struganje uz napredne putanje alata i tehnike mašinske obrade

SolidCAM u jednom paketu daje rešenja za grubu i završnu obradu površina, zajedno sa podrškom za korisnike

Podržan je širok spektar mašina - 2-osni strugovi, konfiguracija sa višekanalnim i viševretenim mašinama, pa i najkompleksnije kombinovane mašine sa istovremenim glodanjem i struganjem (Multi Task ili Mill-Turn).

SolidCAM ima veoma fleksibilan sistem licenciranja, gde svaki korisnik može da izabere tačno konfiguraciju koja mu je potrebna. Kupovinom strugarskog i bilo kog glodačkog modula, dobijate automatski mogućnost programiranja gore pomenutih kombinovanih mašina, strugova sa gonjenim alatima ali i glodalica sa mogućnošću struganja.

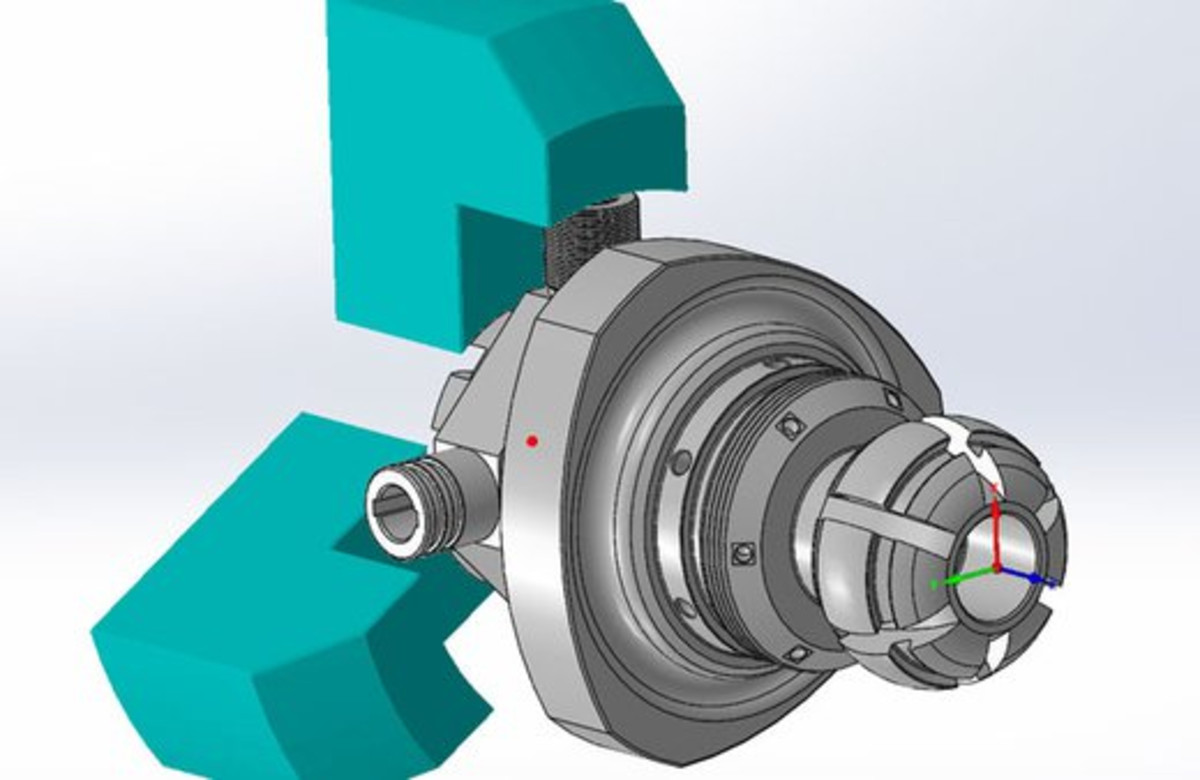

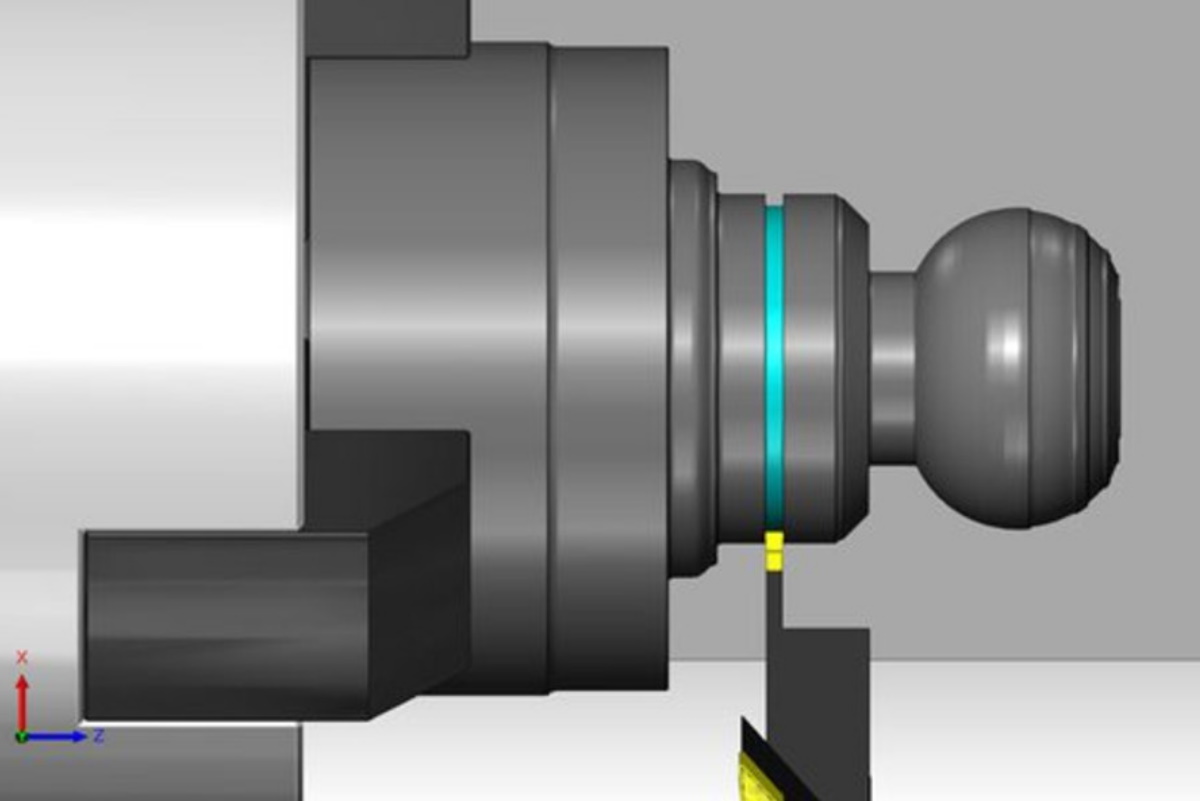

Fixture Definition

Standard Fixture Libraries are available for adding specialized fixtures in the assembly to ensure the protection of the entire Turning tool from crashing into the fixture.

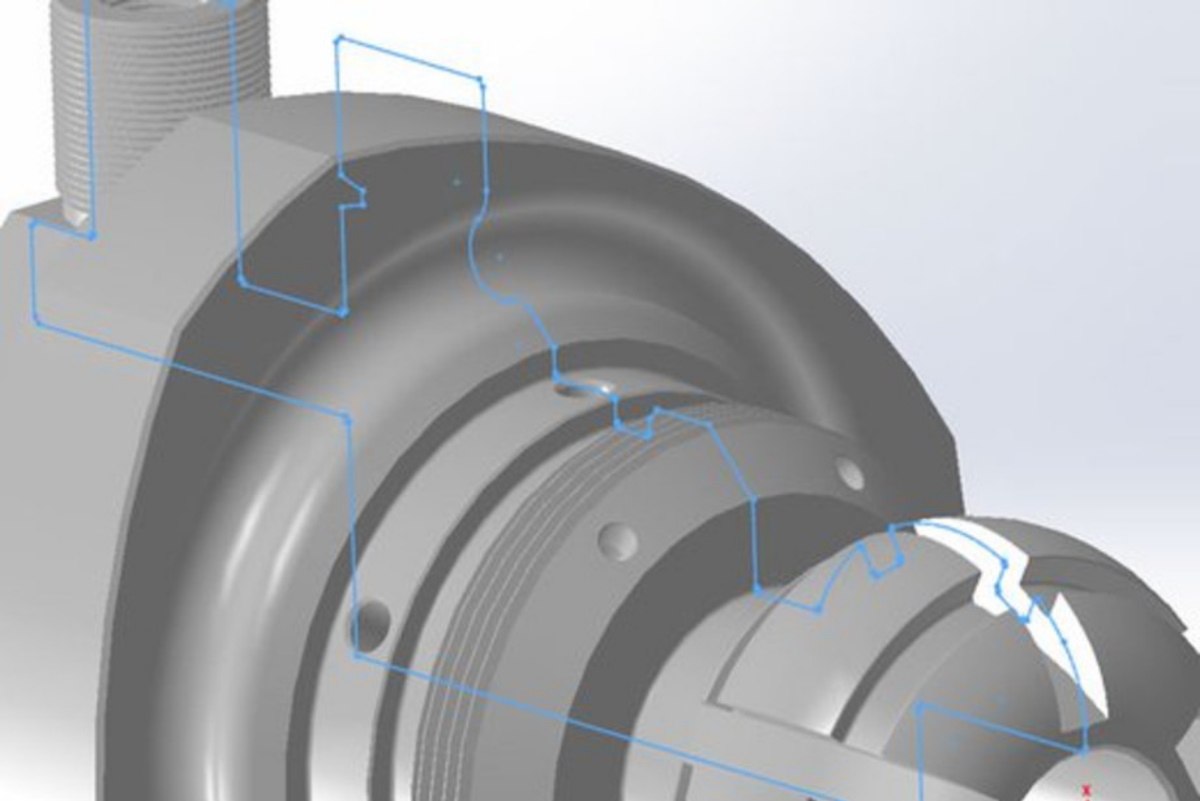

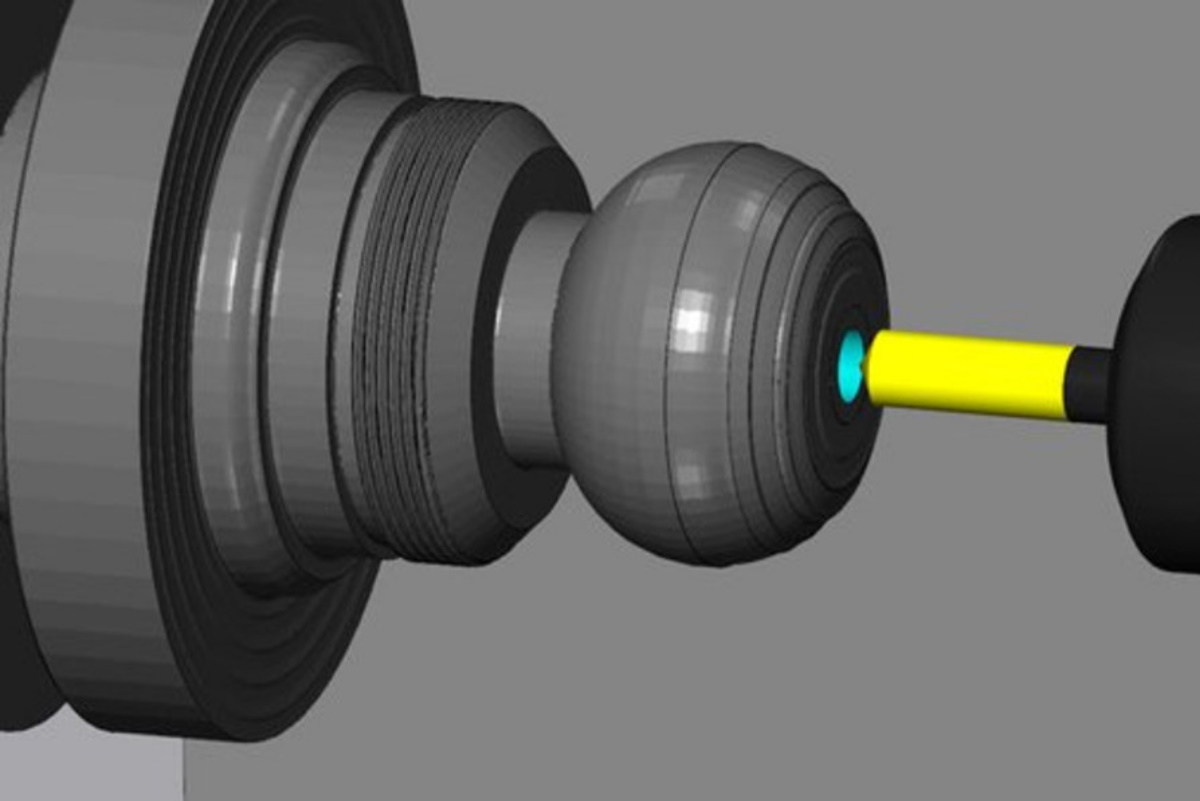

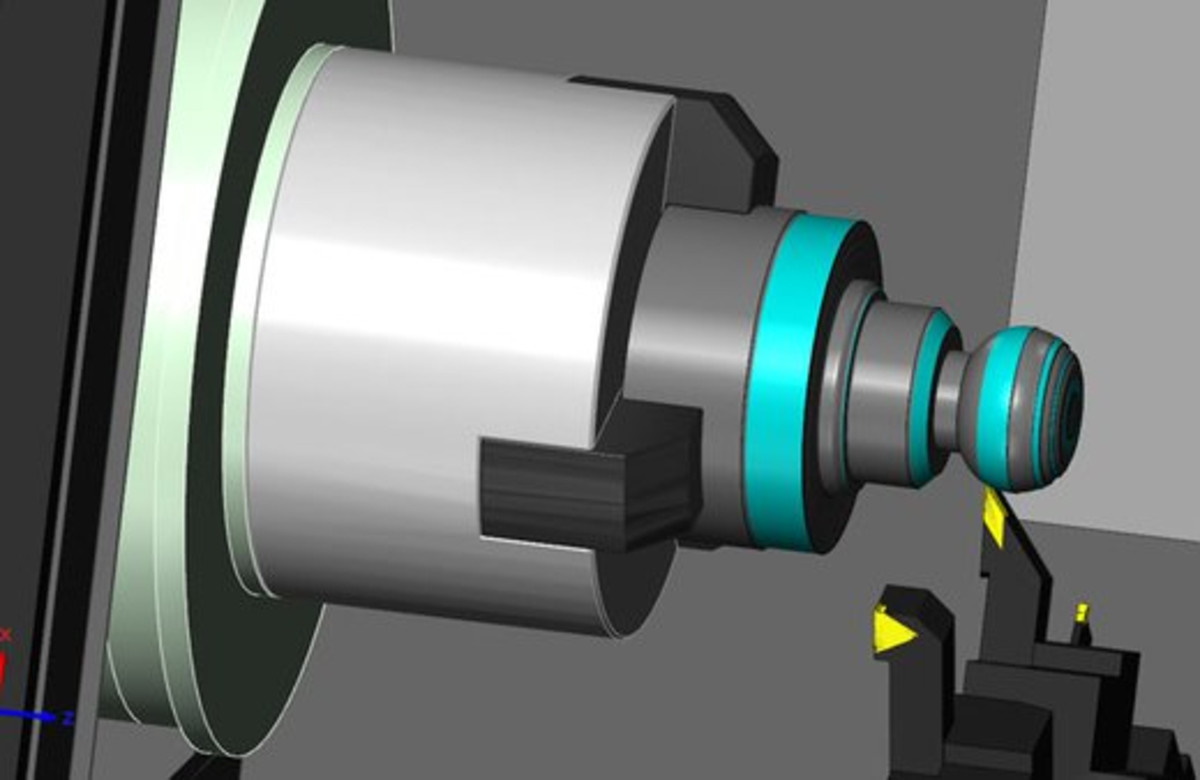

Solid Envelope

Turning Envelopes of complex parts are automatically generated to quickly Turn the outermost profile of the part.

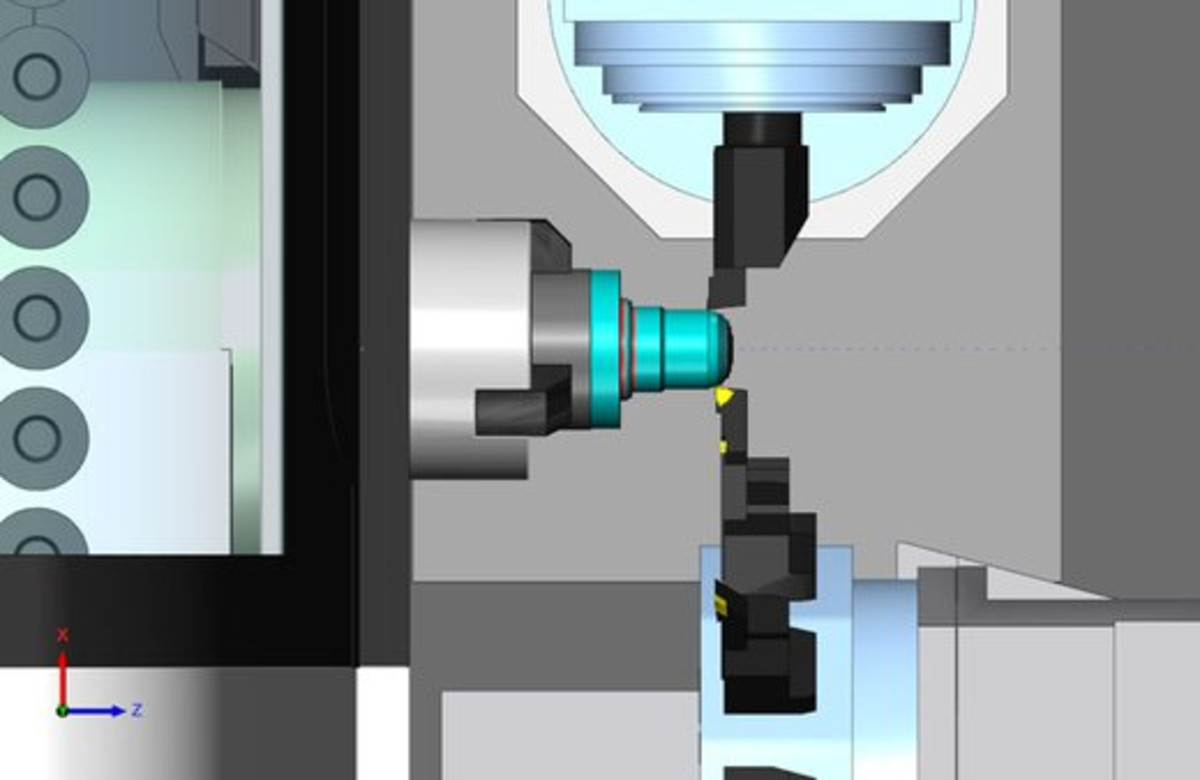

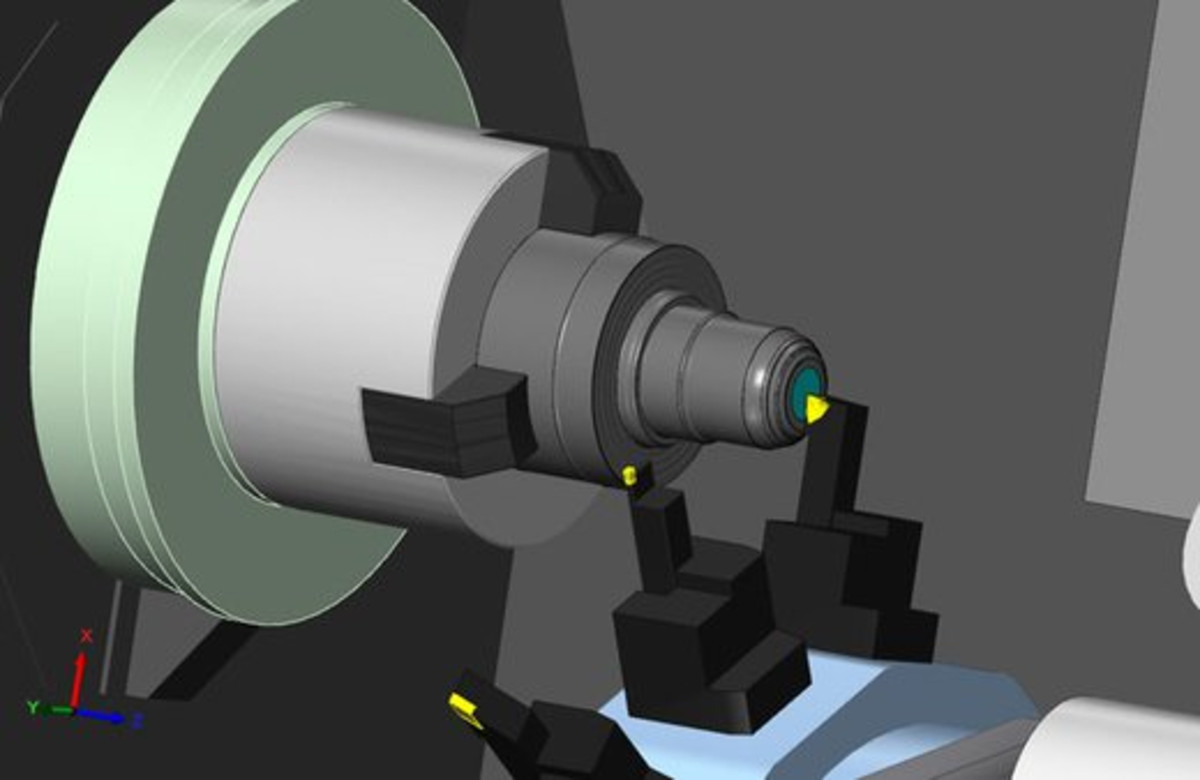

Balanced Turning

Allows you to use two tools to work simultaneously, or in trailing mode, performing Roughing and Turning of long or large parts.

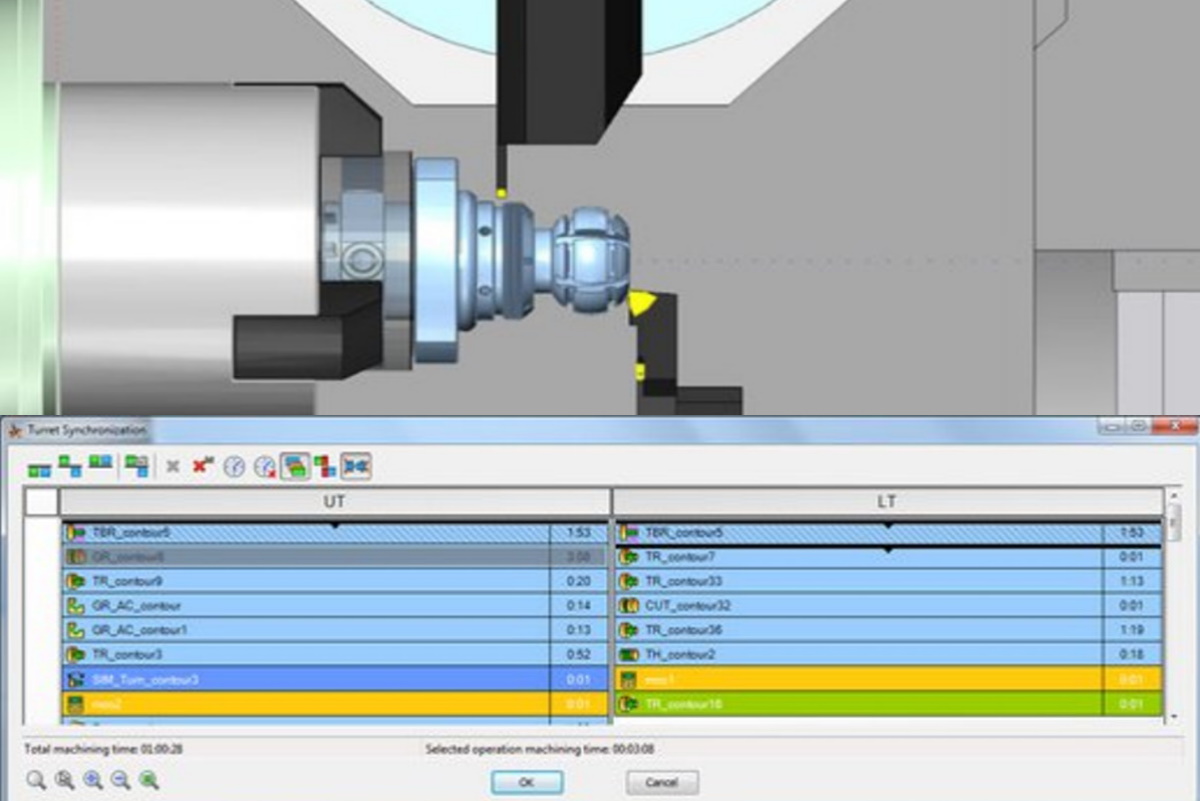

Multi-Turret Synchronization

SolidCAM provides powerful tools to synchronize your Multiple Turret machines. A machining time line, with all operations and simple commands, enables you to align operations that will be synchronized. Afterwards, you can see the result of synchronization in the Machine Simulation.

Drilling

Enables you to a drill along an axis of rotation without defining any geometries.

Threading

Allows you to Thread Internal, External, Longitudinal or Facial Holes, while different cycles, working strategies and built-in threading standards are also supported.

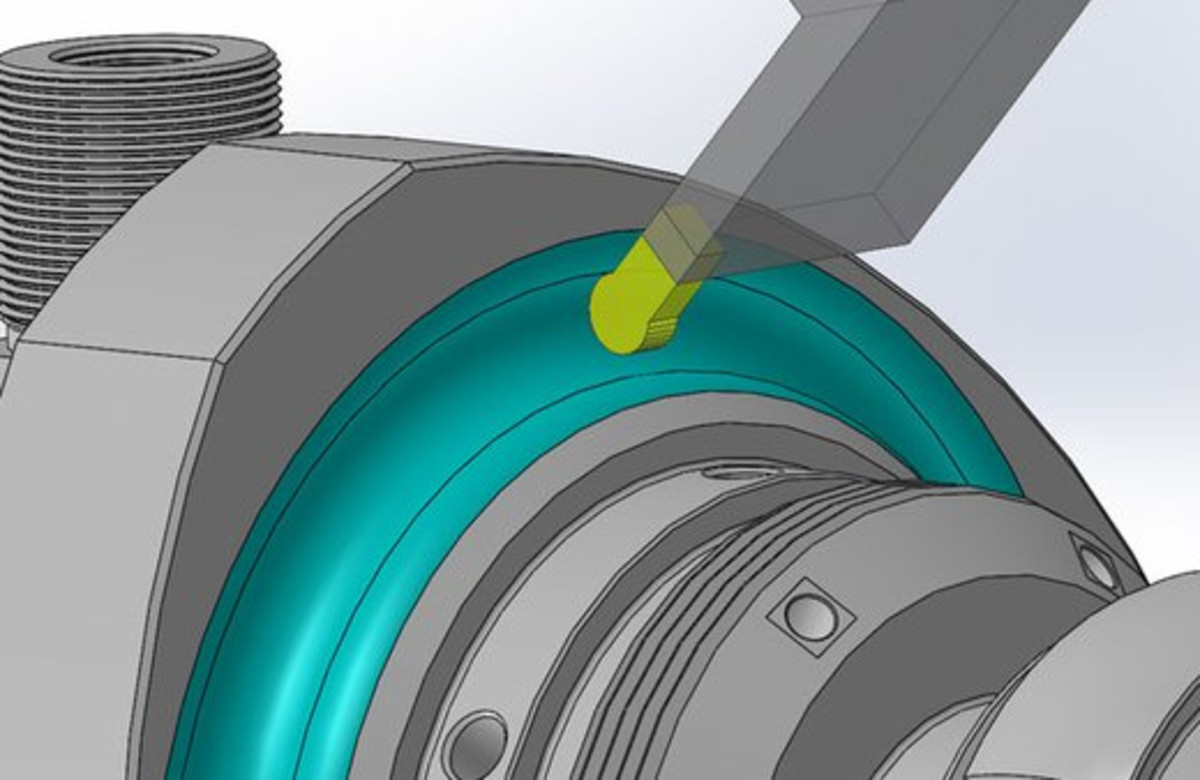

4th Axis Sim. Turning

Enables you to perform machining of a curved profile using B-axis tilting capabilities of your tool. This operation is useful for machining of undercut areas in a single machining step, and supports External Rough Tools and External Groove Tools.

Manual Turning

Gives you the power to perform Turning according to your own geometry, regardless of a stock model, target model, or envelope.

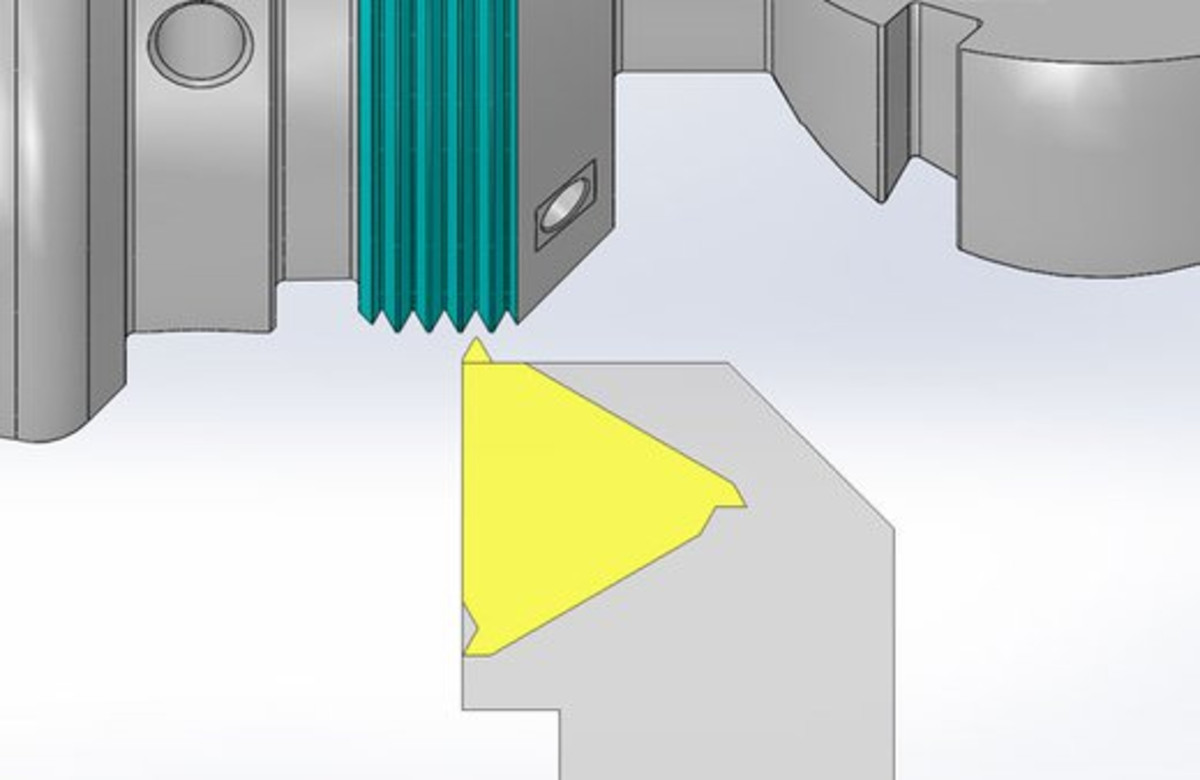

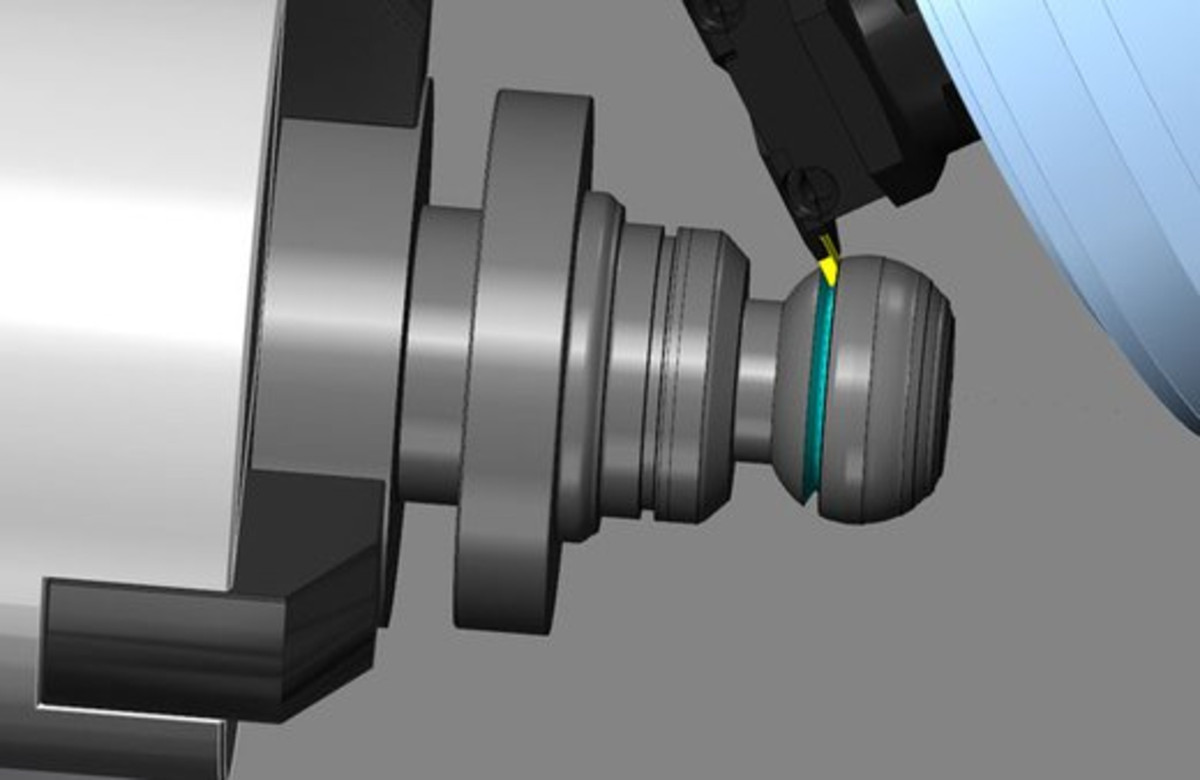

Grooving

Allows you to create Longitudinal (internal/external) or Facial Grooves resulting in a tool path that can use single or multiple machine cycles, or generate tool movements (G0, G1). The advanced Break Edge option is used for handling internal and external corners.

Angled Groove

Enables you to perform internal or external inclined grooves, at any defined angle.

Face Turning

Perform Turning operations of facial profiles.

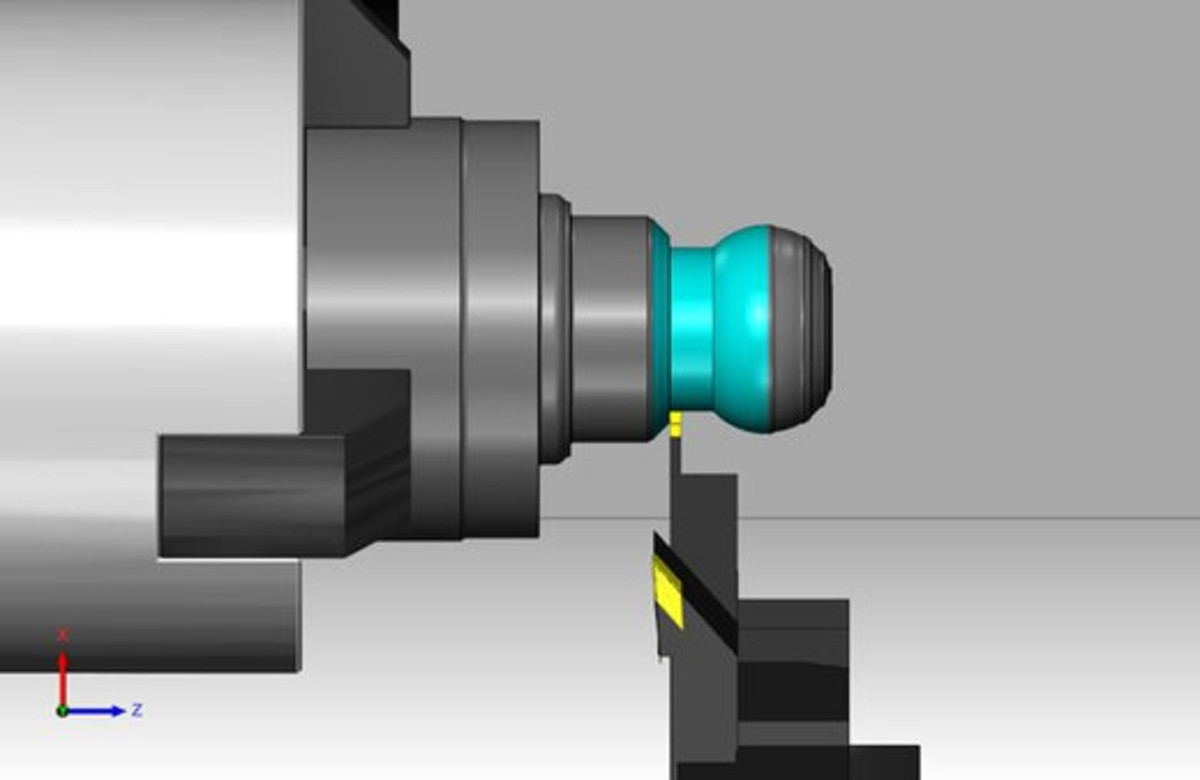

Profile Turning

Enables you to Turn Longitudinal or Facial Profiles resulting in a tool path that can either use the Turning cycles of your CNC (if so equipped), or generates all tool movements while avoiding gouges with the target.

Cut Off

Cut off the part or create a groove with the same width as the tool, using CNC-machine cycles. Chamfers and Fillets can also be created during the cutting.