Suština primene DELMIA aplikacija za simulacije proizvodnog procesa jesu unapređenje bez remećenja tekućih poslova:

- ispitajte uticaj nove mašine, linije, radnog mesta na proizvodni proces

- definišite prostor u kome se odvija proizvodnja i detektujte sporne tačke (ukrštanja, zastoji, bezbednosni rizici, itd)

- unesite izmene, unapređenja, novu opremu i analizirajte u digitalnom blizancu posledice na proizvodni proces

- budite sigurni da će nova mašina, robot, linija, čak i ako je prva svoje vrste u vašem pogonu, zaista doprineti efikasnosti u dovoljnoj meri da se investicija isplati u prihvatljivom roku.

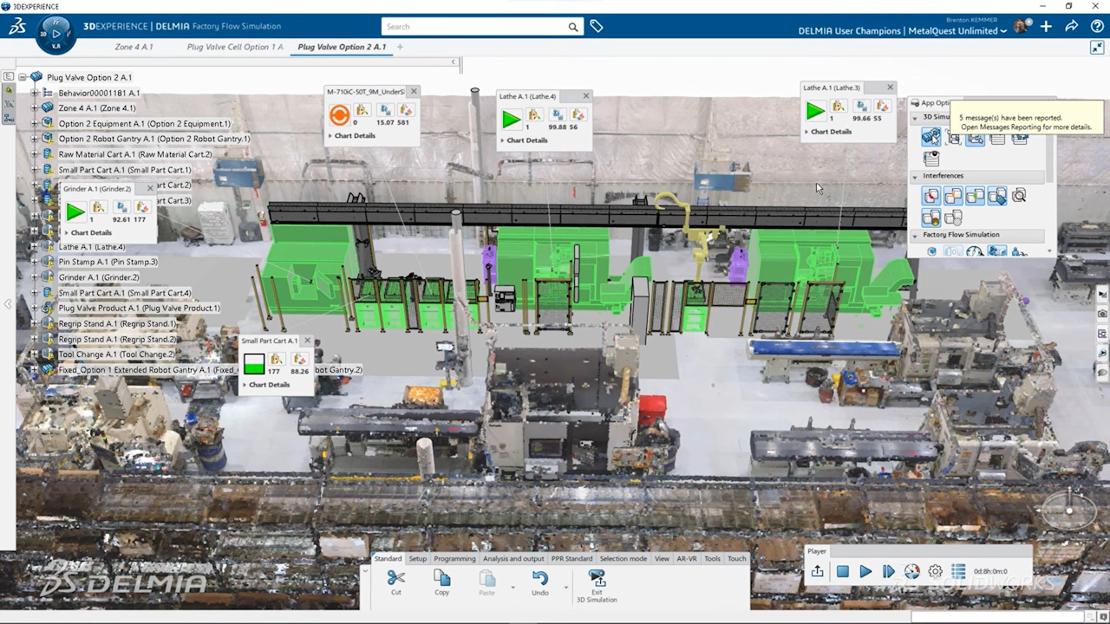

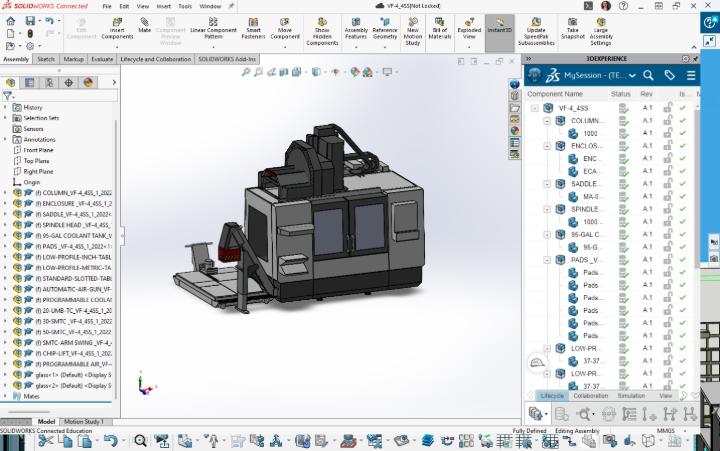

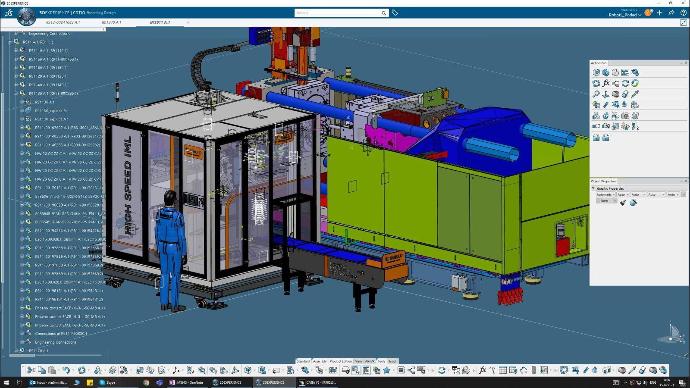

SLIKA: Digitalni blizanac vaše proizvodnje

- 3D prikaz - oblak tačaka, 2D outline pogona, 3D CAD novih mašina, STL komponenti i radnika > apsolutno sve možete uneti na model u formatima kojima raspolažete

- detalji za svaku radnu stanicu - strugovi, glodalice, brizgaljke, linije, roboti > instant simulacija realnih uslova rada

- ispod pogledajte ceo video odakle je i ova slika.

VIDEO: Kratki uvod u Factory Simulation rolu

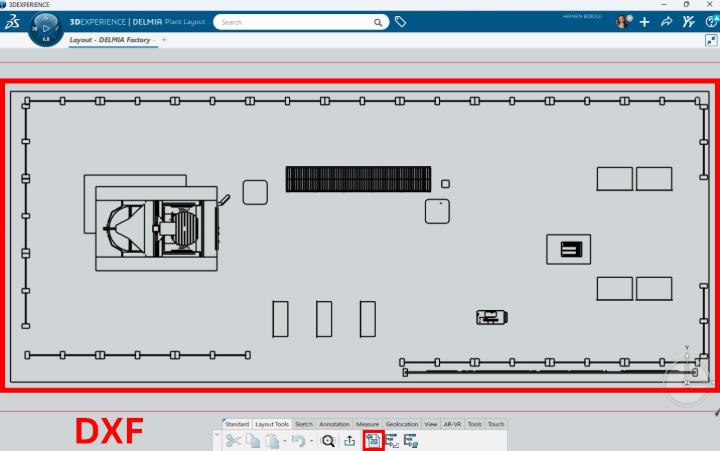

Factory Floor Layout - jednostavni 2D prikaz u DXF fajlu na 3DEXPERIENCE platformi

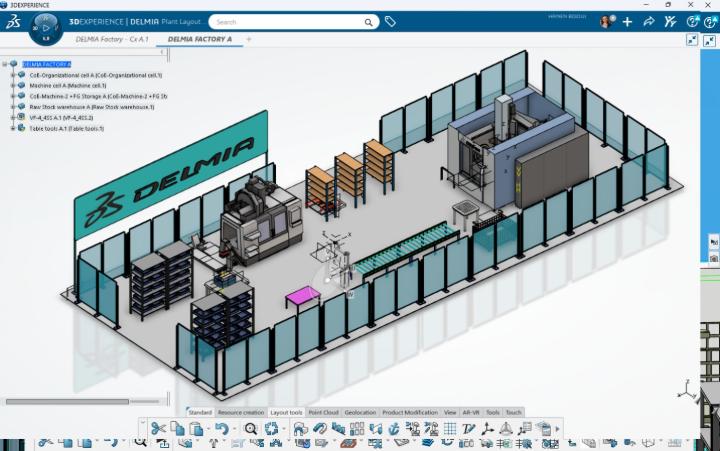

Factory Floor Layout - sukcesivno možete dodati kompletne 3D modele vaših mašina, proizvodnih linija i sve prateće opreme za potpuni kontekstualni prikaz celog pogona

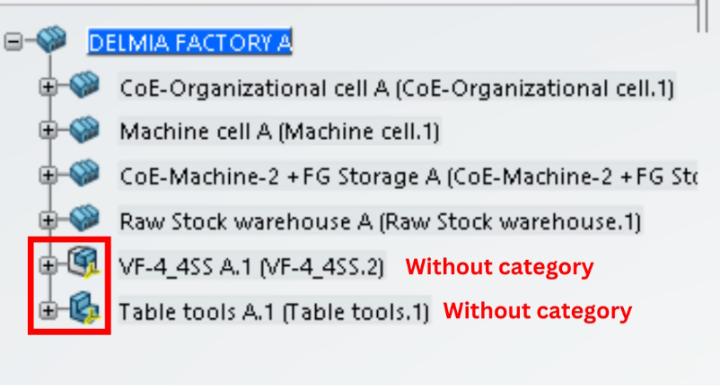

SLIKA: Factory Floor Simulation detalj interfejsa aplikacije sa 3D modelom vaše CNC mašine iz SolidWorks softvera koja se dodaje u plan pogona

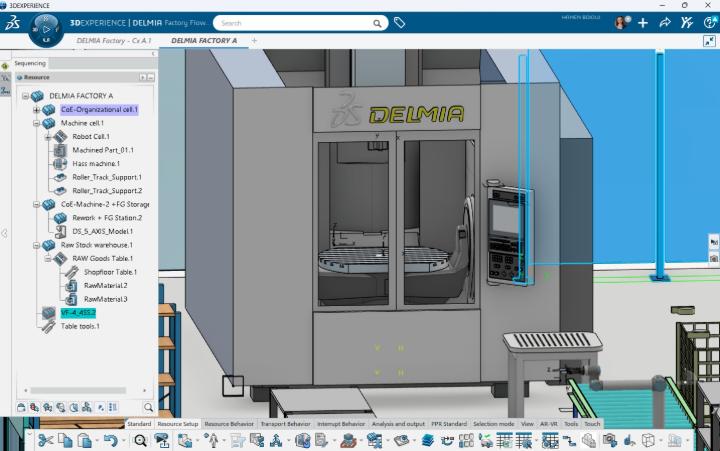

SLIKA: Direktna integracija sa SolidWorks softverom odakle svoje delove za proizvodnju, obratke i 3D modele pribora za stezanje dodajete na 3DEXPERIENCE platformu direktno u Factory Floor Simulation aplikacije

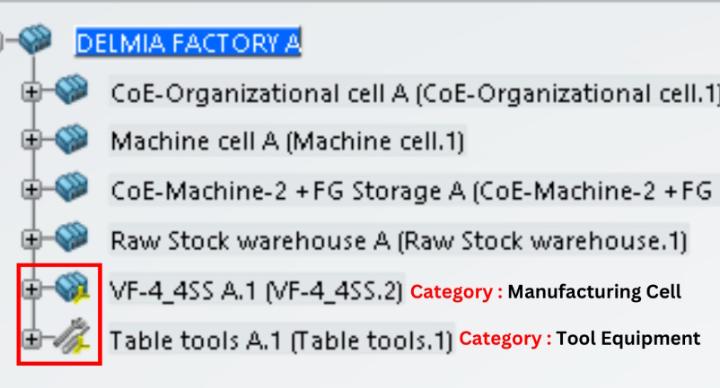

SLIKA: DELMIA stablo pokazuje CAD modele proizvoda koji su uneti iz SolidWorks softvera bez kategorizacije (Image: ChampionXperience.)

SLIKA: DELMIA stablo pokazuje CAD modele proizvoda unetih iz SolidWorks softvera sa dodatom kategorizacijom resursa (CNC mašina VF4 kategorizovana kao proizvodna jedinica i radna plača kao Oprema za alat (Image: ChampionXperience.)

Zašto vam je potrebna simulacija proizvodnog procesa?

Unapređenje proizvodnog procesa

Stiže nova mašina? Planirate dupliranje linija za povećanje kapaciteta proizvodnje? Razmišljate o integraciji robota? Gužva u proizvodnji povećava rizike od povreda?

Napravite "virtuelnog blizanca" cele vaše proizvodnje i lako i brzo isplanirajte svaku izmenu, izmerite prednosti i mane nove postavke, otklonite rizične tačke, izračunajte povećanje efikasnosti različitih varijanti za svaki korak proizvodnje.

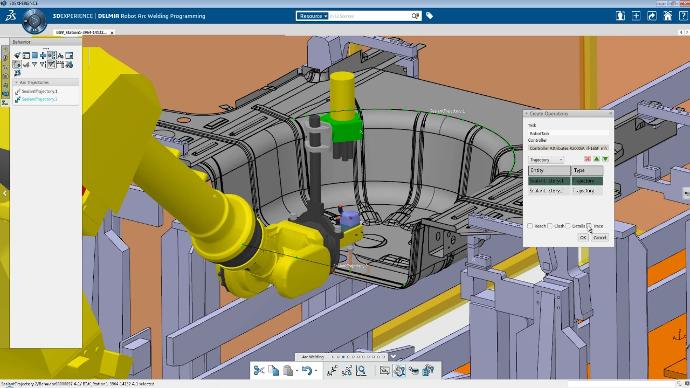

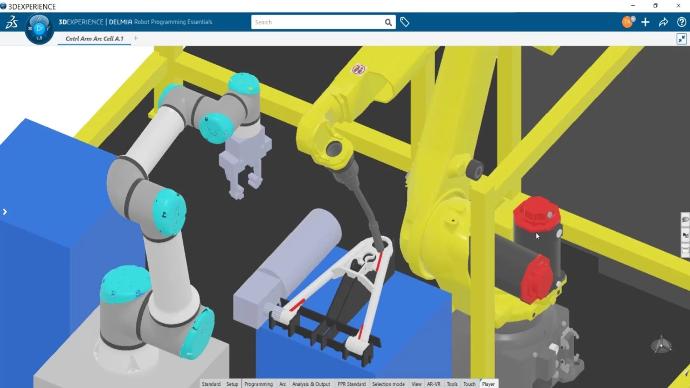

Automatizacija i integracija robota

Primena robota u proizvodnji beleži neprekidni rast ali niste sigurni da li će robot na nekoj poziciji u vašoj proizvodnji zaista doprineti efikasnosti? Da li će ugroziti bezbednost drugih ljudi? Da li će biti u koliziji sa drugom opremom i samim prostorom?

Aplikacije za simulaciju proizvodnje podrazumevaju i programiranje robota i vizuelnu simulaciju njegovog kretanja!

Jednostavno planiranje svakog koraka

Uvek su nova unapređenja podrazumevala zastoje pa i prekide proizvodnje - uvek je morao taj "jedan korak nazad za dva koraka napred". Simulacijom proizvodnog pogona ovo više nije prepreka.

Konačno možete znati kada ste konačno iscrpeli raspoložive resurse i ROI novog prostora ima smisla!

VIDEO: Primer primene aplikacija u praksi

- skeniranje proizvodnog pogona i kreiranje oblaka tačaka

- upload 3D prikaza proizvodnje na 3DEXPERIENCE platformu

- separacija fizičkog okruženja i opreme kako bi 3D model bio fleksibilan za izmene

- ovo dalje omogućava inserte drugih 3D modela (CAD, STL) sa prikazom mašina, robota, linija pa i radnih pozicija za ljude

- a zatim i simulaciju proizvodnog procesa sa aktiviranim pogonom i mašinama i robotima u pokretu

Detaljnije o DELMIA Factory Floor Engineer roli (engleski jezik)

A Factory Simulation Engineer specializes in optimizing factory layouts and production workflows through simulation and manufacturing engineering. This role is vital for enhancing efficiency and cost-effectiveness in modern production processes. Using advanced simulation software, like those available on the 3DEXPERIENCE platform, these engineers create virtual models of manufacturing environments to evaluate production scenarios, improve operational performance, identify bottlenecks and validate design choices before physical implementation.

This role includes access to 24 applications on the 3DEXPERIENCE platform. It is also designed to enhance various aspects of factory simulation and layout design. Among these apps, Plant Layout Design and Factory Simulation are among the most important to this role. This is because they enable engineers to create efficient factory layouts and analyze material flows comprehensively. As a result, it’s important for SOLIDWORKS users to learn how these tools integrate with SOLIDWORKS and how this synergy facilitates seamless design and simulation processes.

- Create and import layouts: Make new, or bring in current, factory layouts.

- See material flow: See how materials move through the factory.

- Predict performance: Predict production speed, how much equipment is used and where problems might happen.

- Improve layouts: Make better layouts, plan paths for materials and organize maintenance and shifts.

- Simulate random events and what-if scenarios: Users can mimic unexpected events, like machine breakdowns or missing parts, and test new setups.

- Model behavior: See how robots and people move and act in the factory.

- Manage AGV Traffic: Manage the movement of automated guided vehicles (AGVs) safely.

- Track and report KPIs: Monitor performance measures and share reports.

- Designers of factory layouts and equipment.

- Manufacturing engineers who improve production processes.

- Process planners focused on workflow.

- Industrial engineers who optimize systems.

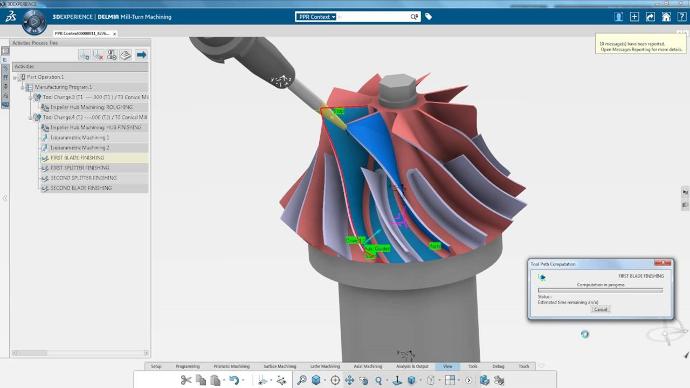

The Plant Layout Design app is a crucial component of the Factory Simulation Engineer role. It enables engineers to create and optimize factory layouts in a collaborative 3D environment. This app allows users to:

Design realistic layouts by defining the positions of equipment and workstations.

Visualize the spatial relationships and flow of materials within the factory.

Validate the layout against production requirements, ensuring efficiency and safety.

A key feature in Plant Layout Design is the ability to assess the footprint, or exact spacing of each component, machine or area occupied within the facility. Footprints are essential for optimizing space, boosting efficiency and enhancing material and personnel flow. The app also supports direct CAD file imports, like DXF, allowing designers to incorporate precise layouts with ease, paving the way for a streamlined manufacturing environment.

Within the Plant Layout Design app, designers can insert resources from a catalog, or directly from the 3DEXPERIENCE database, into the factory layout. Based on the assigned permissions, users may not have rights to modify all attributes of a resource, but they can:

Create mechanical ports for connecting resources.

Insert existing resources and adjust their parameters to fit the layout requirements.

This workflow makes resource management straightforward, allowing SOLIDWORKS users to move seamlessly between design and simulation tasks.

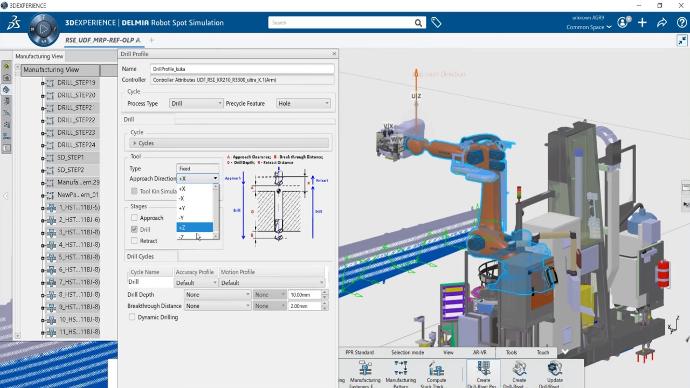

As demonstrated below, a CNC machine can be successfully imported into a factory layout.

In DELMIA, resources are categorized into “Working” and “Non-Working” resources to define their roles in the production process.

Working resources: These are programmable elements (such as NC machines, conveyors, workers and robots) that actively perform operations and move parts through the production line.

Non-working resources: These provide support (like storage, products and transport equipment) without directly executing tasks.

On the 3DEXPERIENCE platform, Physical Products serve as the default objects, but they can be transformed into categorized resources. Users can do this in two ways:

Use the “Generate a Resource” command to convert a Physical Product to the designated resource type. This change is permanent and cannot be reversed.

Create a New Resource Object and nest the Physical Product within it, providing flexibility if you plan to reuse the same product as a different resource. Additionally, 3D Parts can be used instead of Physical Products for this purpose.

The Factory Simulation app focuses on simulating material flows and production processes within the factory. It provides tools for:

- Analyzing how materials movethrough the production line to identify potential bottlenecks.

- Predicting the impact of different scenarios on production rates and resource utilization.

- Validating workflows to ensure that operations run smoothly and efficiently.

The integration of SOLIDWORKS with DELMIA’s Factory Simulation Engineer role within the 3DEXPERIENCE platform is transformative. It enables SOLIDWORKS updates to be reflected in DELMIA simulations instantly — ensuring alignment across design and simulation activities. As a result, organizations can enhance collaboration, minimize lead times and respond swiftly to production changes.

For example, a furniture manufacturer launching a new product line can use this integration to maintain design consistency and analyze various factory layouts in real time. Changes in SOLIDWORKS are reflected in DELMIA simulations, allowing manufacturers to evaluate the impact of a design change on workflows, resources and production efficiency. This synergy ultimately drives profitability, accelerates time-to-market and reduces costs.

A standout feature of the Factory Simulation Engineer role is its seamless integration with SOLIDWORKS. For instance, a VF-4 4SS Haas CNC machine created in SOLIDWORKS can be saved directly to the cloud through the 3DEXPERIENCE platform. After saving, the machine can be imported into the DELMIA Plant Layout Design application.

For SOLIDWORKS users, this integration opens a new level of functionality: it’s easy to import 3D CAD data into DELMIA’s factory library. By linking SOLIDWORKS models directly to the cloud, engineers can streamline workflows, ensure consistency in their 3D CAD data and eliminate redundant steps in model preparation. This connection enables factory layout and simulation tasks to be managed from one platform, accelerating the design-to-production timeline.

The Factory Simulation Engineer role on the 3DEXPERIENCE platform represents a powerful tool for enhancing factory design and simulation. With its seamless integration with SOLIDWORKS, engineers can efficiently design, optimize, and simulate production layouts, bringing their factory visions to life. As manufacturers adapt to Industry 4.0, the ability to simulate production processes in a 3D environment has become essential to maintaining competitiveness and achieving operational excellence. The Factory Simulation Engineer role is therefore not just a tool but a strategic asset, driving efficiency, cost savings and productivity across manufacturing operations.

DELMIA aplikacije unutar Factory Floor Simulation role na 3DEXPERIENCE platformi za simulacije unapređenja proizvodnih procesa

SLIKA: Prikaz svih aplikacija koje sadrži DELMIA Factory Simulation Engineer rola na 3DEXPERIENCE platformi

Equipment & Layout Engineer

Kreirajte i validirajte alate, mašine i pozicioniranje u proizvodnji kako biste napravili Virtuelnu fabriku gde možete lako i brzo da testirate sve buduće izmene i unapređenja.

Factory Layout Designer

Izbegnite rizike velikih investicija tako što ćete prvo maksimalno eksploatisati raspoložive resurse kroz kreiranje, analizu i optimizaciju pogona na 3DEXPERIENCE platformi stvaranjem efikasnijih rasporeda i procesa.

Factory Simulation Engineer

Simulacija protoka i potrošnje materijala kroz digitalni blizanac vašeg proizvodnog pogona u cilju optimizacije, efikasnosti i profitabilnosti.

Machine & Tooling Designer

Napravite (ili uzmite iz velikih DELMIA biblioteka) kompletnu bazu 3D modela svih vaših mašina, opreme, robota, 3D štampača i alata, sa uključenom njihovom kinematikom u proizvodnji.

Plant Layout Designer

Napredne opcije kreiranja planova proizvodnje i postrojenja koje planerima proizvodnje pružaju mogućnost da unaprede efikasnost svih procesa.

Shop Floor Equipment Engineer

Kreirajte digitalni blizanac svake radne jedinice u vašem pogonu koristeći CAD informacije koje će u DELMIA softveru oživeti i pokazati vam svoje ponašanje u realnim uslovima.

Virtual Commissioning Analyst

Izvršavajte testiranja vaše virutuelne fabrike kroz razne scenarije uz preciznu simulacije kompletnog pogona, mašina, robota, linija i svih povezanih senzora.

Simulacije proizvodnih procesa - DELMIA Factory Automation, Factory Simulation Engineer i Factory Flow Simulation aplikacije