Produžite životni vek alata optimalnim programiranjem rutera svih vrsta za sečenje drveta, kompozita i drugih materijala.

SigmaNEST is the leading router software for programming single or multi-spindle wood and metal CNC routing machines. It’s ideal for high-efficiency production in frame shops, boat, and furniture manufacturers. Single and multi-head management, efficient stack cutting and multi-pass cutting are a few of the advanced features offered by SigmaNEST.

Za sve vaše rutere

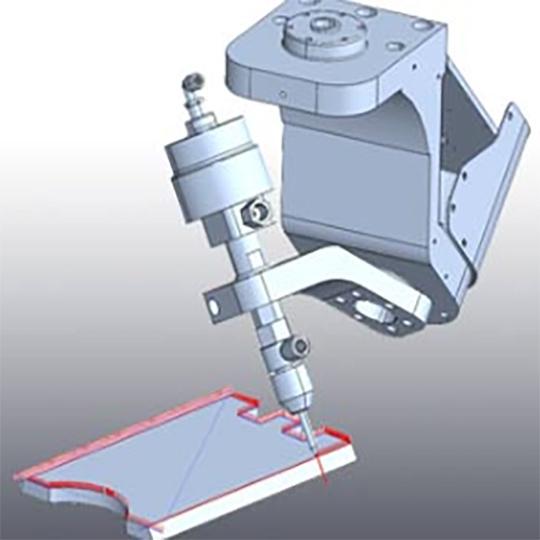

Primenite jedno rešenje za programiranje svih vaših rutera, sa jednim ili više vretena, sa jednim ili više alata sa automatskom izmenom, sa jednostavnim 2D sečenjem ili sa mogućnošću sečenja pod uglom i obaranja ivica.

SigmaNEST rešenje za CNC rutere

Directly import multi-depth information from 3D CAD files

Extend tool life with variable depth control

Maximize material yield through common-line nesting/cutting

Minimize vacuum loss and enhance sheet stability

Auto program runs both sides for near and far sighted

Support for aggregate “I”, “T”, and “L” formations

Advanced NC logic including spiral inward cutting for vacuum hold-down efficiency

Support of automatic and manual cutting for multi-head

Recognition of partial depth and part edge for “auto pocket destruct”

Seamlessly import from solid CAD programs with automatic recognition of 3D models with z-depth

Automatic recognition for gang drilling

Automatic auxiliary for detail correcting

Stability sequencing

Small part handling

Prednosti SigmaNEST rešenja

Single and multi-head management

Efficient stack cutting

Multi-pass cutting

Static nesting for the highest efficiency for cutting times

Tool oscillation to extend bit life

Multi-depth cutting and controls, including Z-depth tab

Z-ramp lead-ins to guard against fires

Contour lead-ins

Mortise and tenon

Metal router riveting

Pocketing

Win more jobs with faster and more accurate quoting

Customize tool order to optimize part quality

Set multi-pass cutting by contour to reduce machine time or nesting to increase vacuum efficiency

Optimize balance between throughput and material yield

Minimize tool and spindle damage by applying ramp-up leadins/leadouts

Extend tool life and part quality with multi-pass cutting features allowing for step down cuts

Considerably reduce cutting time with onion skin tabbing and 3D tabbing

CNC ruteri za drvo i pločevinu - SigmaNEST podržane mašine