SigmaMRP je specijalizovani modul za upravljanje proizvodnim resursima (Manufacturing Resource Planning) koji se integriše sa ostalim komponentama Sigma Suite-a (SigmaNEST, SigmaTUBE, SigmaQUOTE) kako bi obuhvatio celokupan proizvodni ciklus – od pripreme ponude do finalne isporuke.

Dva scenarija upotrebe SigmaMRP softvera:

SigmaMRP - Scenario 01

Bavite se preradom lima, pločastog materijala, cevi, profila i šipkastog materijala i želite prilagođeno rešenje samo za vas. SigmaMRP postaje vaš poslovni sistem od upravljanja odnosa sa klijentima, prodaje, davanja ponuda, kalkulacija proizvodnih troškova, planiranja, praćenja proizvodnje, upravljanja radnim nalozima sa nabavkom, upravljanjem odnosima sa dobavljačima, sve do upravljanja zalihama, magacinskim poslovanjem, pa do isporuke ka vašim kupcima uz prijem i izdavanje računa. SigmaMRP je vaš ERP za proizvodnju u ovom scenariju gde su aplikacije za programiranje CNC mašinama sastavnideo ovog integrisanog rešenja.

SigmaMRP - Scenario 02

Več imate ERP softver u kome upravljate prodajom i nabavkom, ali i svim ostalim procesima ali nikako da uspostavite kontrolu nad pogonima za pripremu i sečenje materijala. SigmaMRP može da preuzme kontrolu nad vašim pogonom za fabrikaciju, dok kroz integraciju sa vašim ERP-om čini kompletan sistem koji komunicira i razmenjuje kritične informacije o zalihama, planovima, rokovima, isporukama... Podrazumeva se da koristite CAD/CAM rešenja za nesting i programiranje CNC mašina jer su ona sastavni deo rešenja.

SigmaMRP - šest moćnih modula:

- CRM

- magacin i nabavka

- Baza proizvoda, poluproizvoda i materijala (artikali, sastavnice), tehnološke rute i proizvodne sastavnice

- ponude i prodajne porudžbine

- upravljanje proizvodnjom

- integrisano poslovanje

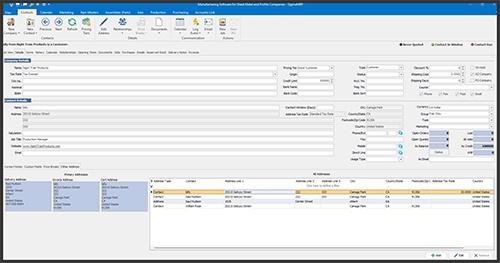

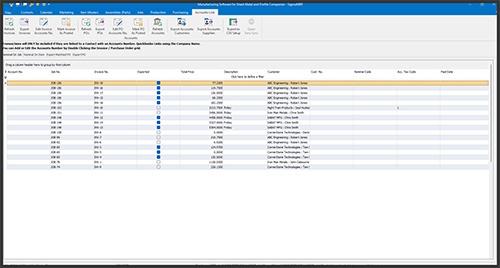

CRM

Track and manage history and interactions with all your customers, suppliers and vendors and use that information to make business decisions

Store customer documents and categorize customers into different groups to streamline downstream processes such as production orders and purchasing

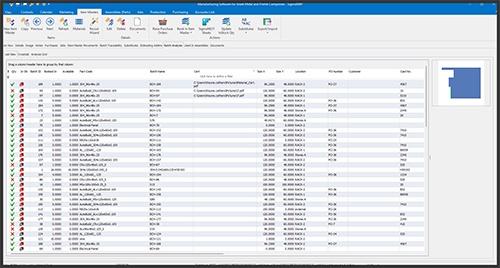

Inventory and Purchasing

Manage and track the full history and usage of some or all your inventory including sheets/plates, tubes/barstock, hardware, buckets of paint and more

Be notified when inventory levels are getting low so more can be purchased or produced

Create and manage purchase orders to suppliers and subcontractors as well as the receiving/booking in process

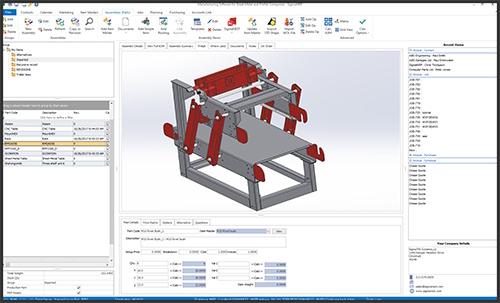

Assemblies/BOMs

Build full assemblies (BOM plus routing steps) and store them for easy quoting

Link assemblies together to create multi layered assemblies with subassemblies

Dependencies between routing steps will be respected when using the SigmaSCHEDULE scheduling solution

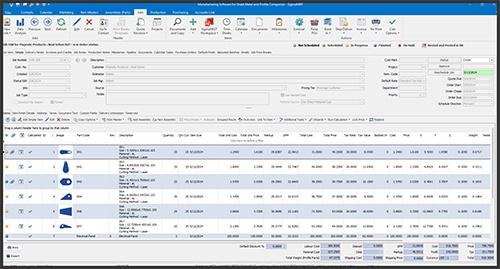

Quotes and Orders

Quickly create highly accurate quotes and production orders with customizable and automated cost calculations and markups

Quote any item from tube laser parts, to flat parts that are cut and bent to full assemblies that require welding and assembly

Quickly see the status of any job such as material allocated, delivery notes created and invoices sent

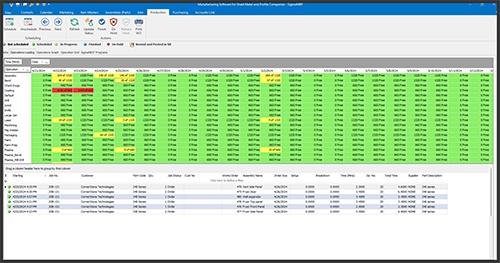

Production Management

View critical data about production orders including expected completion dates of each step of production, production steps currently in process, history of shop floor production for each step

Reschedule, put jobs on hold or even mark all production complete quickly and easily

Accounting Integration

Direct integration with top accounting software packages such as Quickbooks (online and desktop), Xero and Sage

Integrate with your accounting package to send invoices and purchase orders so there’s not need to reenter them

Contacts and account balances are also synced with the accounting software

SigmaMRP - centralizuje proizvodne procese, optimizuje resurse i povezuje sve od ponude do isporuke u jedan jedinstven sistem