SolidCAM za CNC operatere je dodatna aplikacija za SolidCAM korisnike koja im omogućava dodatnu fleksibilnost rada u samoj proizvodnji pružajući operaterima kraj CNC mašina da obave svoje zadatke uz više dodatne kontrole i manje rizika po kvalitet i samu mašinu i alate.

SolidCAM za CNC operatere može se pokrenuti kao zasebna standalone aplikacija ili direktno iz SolidWorks-a.

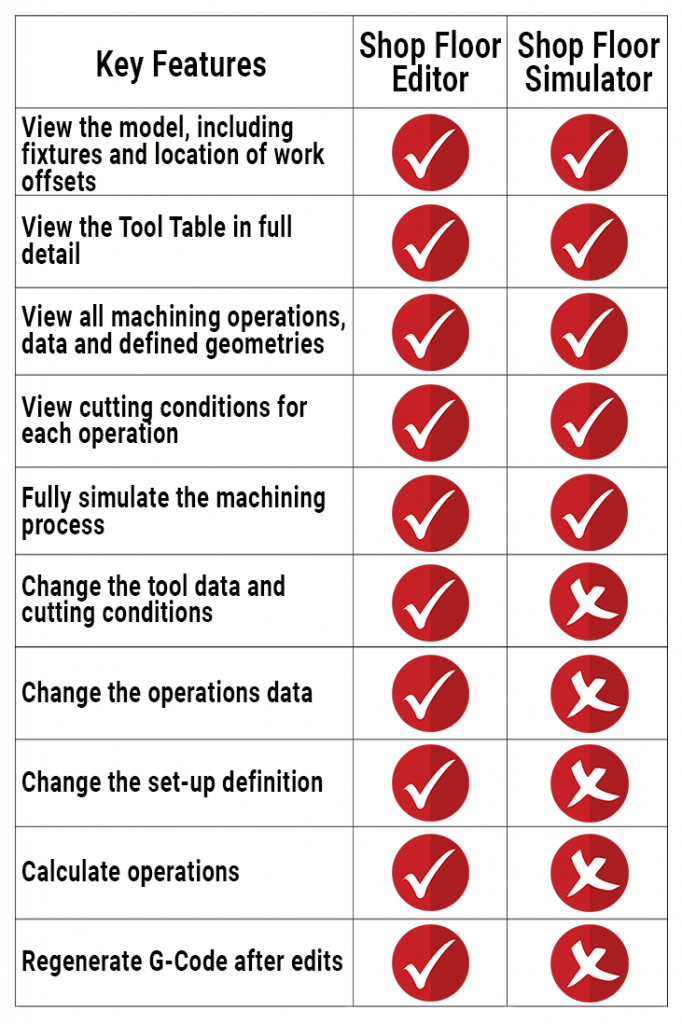

SolidCAM operators dolazi u dva moda:

- Editor Mode - mogućnost izmene, simulacije i generisanja novog G-koda

- Simulator Mode - ograničene funkcionalnosti samo na simulacije mašinske obrade

Uvod u aplikaciju SolidCAM for Operators

Pogledajte kraći video kako vam SolidCAM za operatere pomaže u proizvodnji:

- Minimalizujte oslanjanje na "suve probe" - prođite kroz svaki korak G-koda, skratite vreme pripreme bez potrebe pokretanja programa "u prazno" radi provere.

- Sprečite oštećenja CNC mašine i alata - neka operateri vide kompletnu simulaciju tako da mogu da spreče nepredviđene kolizije.

- Podignite efikasnost u radu - operateri mogu da prave manje neophodne izmene samostalno, bez potrebe da svaki detalj iskomuniciraju sa CAM programerima koji su već posvećeni sledećem komadu.

- Kompletna slika pored CNC mašine - uz SolidCAM za operatere radnici pored mašina vide sve detalje svake operacije, uključujući alate i pribore, itd.

U praksi, jedna od važnih prednosti primene ovih aplikacija jeste u firmama koje imaju smenski rad, ili povremeno koriste iskustva spoljnih saradnika za programiranje CNC mašina, pa bilo kakva potrebna izmena ne može da se rešava efikasno jer operateri moraju nisu u mogućnosti da odmah dobiju potrebnu podršku i novi G-kod.

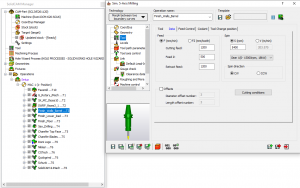

SolidCAM for Operators - Editor Mode

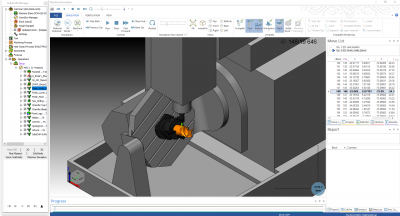

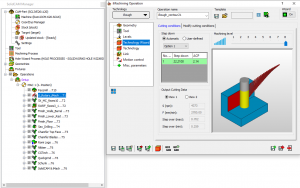

Omogućava operateru mašine da otvori postojeće CAM programe, po potrebi ih izmeni, simulira (uključujući simulaciju mašine) i ponovo generiše G-kod za CNC mašinu.

SolidCAM Shop Floor Editor pruža potpunu kontrolu nad uređivanjem programa i operacija, odmah pored mašine!

U SolidCAM Floor Editor-u je moguće uređivati sve CAM module, tj. glodanje, struganje, Mill-Turn, iMachining itd.

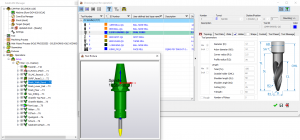

SolidCAM for Operators - Simulator Mode

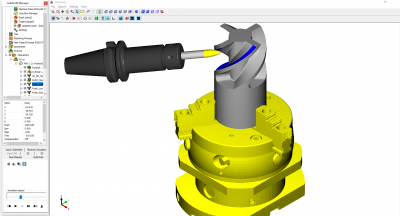

Omogućava rukovaocu mašine da vidi potpunu simulaciju CAM dela, vidi listu upotrebljenih alata sa svim detaljima, da razume način i metodologiju stezanja komada, da vidi početne položaje G-koda i na kraju da vidi simulaciju pre pokretanja G-koda na CNC mašini. Editovanje i pormene nisu dozvoljene na CAM delu.

SolidCAM Shop Floor Simulator dostupan je sa verzijom SolidCAM 2021.

Večiti problemi nadležnosti i raspoloživih alata za rad

Uobičajen problem u mnogim mašinskim radionicama jeste to što može doći do potpunog neusaglašavanja između programera, koji su odgovorni za određivanje strategije obrade, i CNC operatera, koji su odgovorni za verifikaciju CNC programa.

Potrebno je da program koji su pripremili programeri ne sadrži greške, da nema kolizije i da će na kraju CAM deo biti izveden besprekorno i u pravim dimenzijama.

Zašto vam treba SolidCAM za operatere?

CNC operater će neizbežno morati da postavi programeru pitanja, s tim što, će programer biti zaokupljen programiranjem sledećeg dela - svakodnevne neprijatnosti!

Takođe, ponekad su potrebne manje promene u programu, poput promene uslova rezanja, promene pomaka alata itd. To takođe može dovesti do velikih problema u toku rada, na primer kada programer i operater rade u različitim smenama.

Rešenje: SolidCAM for Operators!

Dva specijalna modula SolidCAM-a (Simulator i Editor mode) za CNC operatere, rešavaju dilemu koja postoji u gotovo svakoj mašinskoj radionici, i pojednostavljuje rad mašinske radionice!

Shop Floor Editor - iMachining Level Adjustment

Shop Floor Editor - Tool Data Adjustment

Shop Floor Editor - Change Tool

WEBINAR

SolidCAM for Operators

Pogledajte detaljni opis funkcionalnosti i uloge SolidCAM for Operators ponude koja može značajno da unapredi fleksibilnost vaše proizvodnje.

Želite više fleksibilnosti u radu svojih CNC mašina? Tražite prezentaciju i ponudu od Solfinsa!

Discover the Advantages of SolidCAM for Operators

In today's fast-paced manufacturing world, efficiency and precision are crucial. SolidCAM is an innovative CAM software solution that brings a host of benefits for CNC operators, making it a go-to choice in the industry. Whether you’re working with milling, turning, or multi-axis machining, SolidCAM offers tools that streamline the process, reduce errors, and improve overall productivity. In this article, we'll explore the specific advantages of SolidCAM for operators and how it can transform your manufacturing workflow.

One of the primary advantages of SolidCAM for CNC operators is its user-friendly interface. SolidCAM integrates seamlessly with popular CAD systems, such as SolidWorks and Autodesk Inventor, making the transition smooth for operators who are familiar with these design tools. The software's intuitive layout and easy-to-navigate features allow operators to quickly understand the functionalities, significantly reducing the learning curve.

For operators looking for user-friendly CAM software, SolidCAM’s well-designed interface is one of the best in the industry.

One standout feature that operators love is iMachining, a module within SolidCAM that offers revolutionary toolpath optimization. This feature not only ensures faster machining times but also improves tool life by reducing wear and tear. Operators can rely on iMachining's intelligent toolpaths to produce accurate parts in a fraction of the time compared to traditional methods.

SolidCAM takes a proactive approach to avoid costly machining errors. Its real-time simulation capabilities allow operators to view the entire process before running it on a physical machine. This helps in catching potential collisions, toolpath errors, or setup issues in advance. The SolidCAM Simulator provides accurate visualizations, enabling operators to fine-tune their processes, improving both safety and efficiency.

By using SolidCAM, operators can achieve increased productivity due to shorter cycle times and minimized downtime. The software's automation features allow for a smoother and more efficient workflow, with fewer manual interventions required during the machining process. Operators can also handle more complex tasks, thanks to SolidCAM's robust multi-tasking functionalities, which combine milling and turning operations into one seamless process.

Tool management is a critical part of CNC operations, and SolidCAM addresses this with its advanced tool management system. Operators can store, manage, and access information about tools, such as geometry, material, and usage history, ensuring that they are always using the right tool for the job. This not only improves efficiency but also helps reduce tool wear, prolonging the lifespan of expensive cutting tools.

SolidCAM integrates seamlessly with a wide range of CNC machines, making it highly adaptable for operators in different industries. Whether you are working with 3-axis, 5-axis, or multi-axis machines, SolidCAM provides customizable postprocessors that ensure smooth communication between the software and your machine, resulting in flawless operations. Operators can rest assured that they are working with software tailored to their specific equipment.

One of the standout features that CNC operators will appreciate is SolidCAM’s multi-axis machining capabilities. With simultaneous 5-axis machining, operators can achieve more complex geometries with fewer setups, significantly reducing the overall machining time. This is crucial for industries that require precision and efficiency, such as aerospace, automotive, and medical device manufacturing.

Operators can save significant time using SolidCAM’s customizable postprocessors. These postprocessors translate the CAM software’s instructions into the language your CNC machine understands, ensuring efficient, error-free operations. With SolidCAM, operators have access to a vast library of postprocessors or can have one custom-tailored to meet specific machine requirements.

Operators can also benefit from SolidCAM’s extensive training materials and support system. SolidCAM offers a wealth of resources, including video tutorials, user forums, and technical support, ensuring that operators have everything they need to master the software. Whether it’s learning advanced techniques or troubleshooting issues, operators have access to all the tools they need for success.

FAQ: SolidCAM for Operators

Najčešće postavljena pitanja

SolidCAM is an advanced CAM software solution that simplifies CNC operations, offering features like toolpath optimization, simulation, and multi-axis machining, all aimed at improving efficiency and reducing errors.

iMachining uses intelligent toolpath algorithms to reduce cutting forces, which minimizes wear and tear on tools, prolonging their lifespan.

Yes, SolidCAM is compatible with multi-axis CNC machines, including simultaneous 5-axis and mill-turn machines, allowing operators to handle complex parts with ease.

SolidCAM offers a user-friendly interface and extensive training resources, making it easy for operators to get up to speed with the software.

Yes, SolidCAM provides real-time simulation, allowing operators to preview the entire machining process and catch errors before they happen.

SolidCAM integrates seamlessly with popular CAD software like SolidWorks and Autodesk Inventor, ensuring a smooth workflow from design to production.

SolidCAM is widely used in industries such as aerospace, automotive, medical devices, and more, where precision and efficiency are critical.

SolidCAM’s toolpath optimization, multi-axis machining, and postprocessor customization help operators reduce cycle times by streamlining the machining process.

SolidCAM offers a vast library of postprocessors and the option to customize them to suit specific CNC machines, ensuring error-free operations.

Operators have access to SolidCAM’s extensive library of tutorials, user forums, and technical support, ensuring they can quickly find answers and guidance.

SolidCAM za CNC operatere - SolidCAM for Operators