Delmia 3DEXPERIENCE Robotics

PROGRAMIRAJTE I SIMULIRAJTE RAD VAŠIH INDUSTRIJSKIH ROBOTA

DELMIA Robotics biblioteka sadrži preko 2000 industrijskih robota spremnih za simulaciju i programiranje!

DELMIA 3DEXPERIENCE programiranje robota

Rešenje za kompletno programiranje i validaciju proizvodnih

procesa koje obavljaju industrijski roboti. Bilo koji broj

robota, bilo koja veličina proizvodnje.

Virtual commissioning - napravite model i testirajte virtuelno

pre nego pustite u rad vašu robotsku ćeliju.

Preko 1500 robota od 15 proizvođača. Online i

offline programiranje.

Pročitajte članak: Kako simulacija rada robota može da obezbedi vašu investiciju u robotiku >>>

Arc Welding

LUČNO ZAVARIVANJE

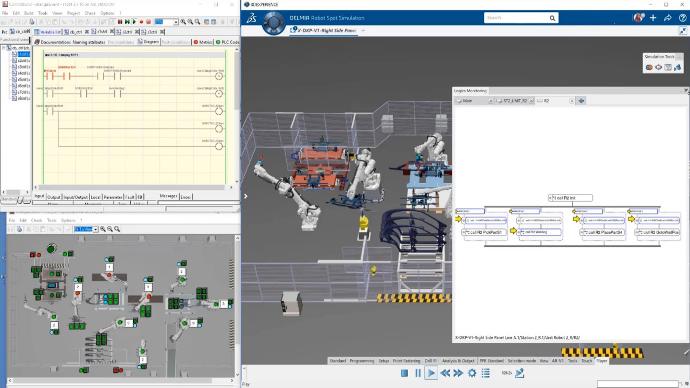

Spot Welding

TAČKASTO ZAVARIVANJE

Surface Simulation

SIMULACIJA POVRŠINSKIH

RADNJI - FARBANJE,

POLIRANJE...

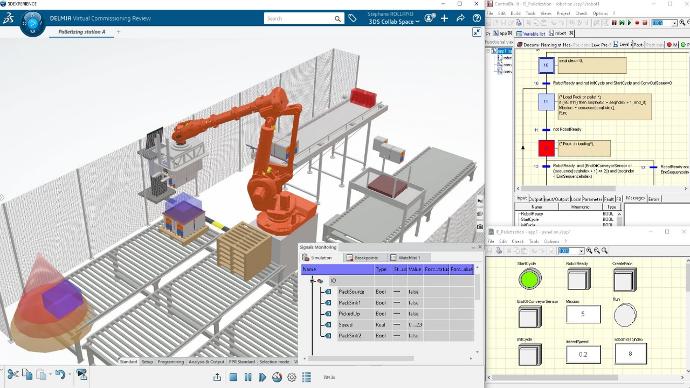

Virtual Commissioning

VIRTUELNA SIMULACIJA PRE PORUČIVANJA ROBOTA I

PUŠTANJA U RAD

Delmia Robotic manipulation

Programiranje i simulacija manipulativnih zadataka za robote

Podržane napredna logičke operacije za programiranje robota (if-then-else,

break, goto, return) kao i luping (for, while) sa lokalnim varijablama

(assignment, arithmetic operations).

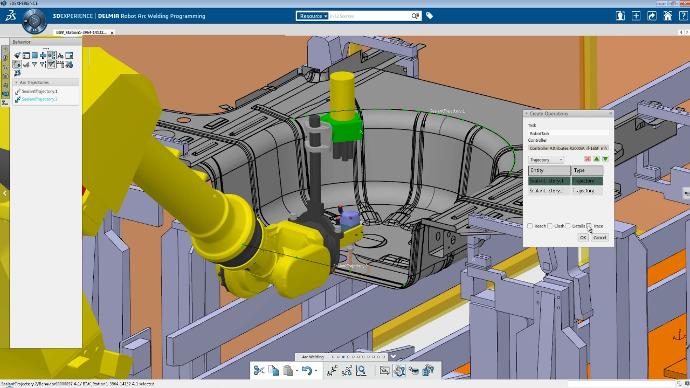

Delmia Arc Welding Programiranje i simulacija

Delmia 3DEXPERIENCE Arc Welding Programiranje i simulacija

Simulacija rada robota sa površinskim zahvatima

(farbanje, poliranje)

Da li imamo vašeg robota u Delmia 3DEXPERIENCE bazi?

Simultan rad više robota na istom zadatku

Da li imamo vašeg robota u Delmia 3DEXPERIENCE bazi?

Delmia Equipment Engineering aplikacija

Kreirajte i validirajte kinematske modele proizvodnih ćelija

Dodelite inverznu kinematiku

Definišite kontrolere i upravljajte grupama koje se kreću

Definicija "HOME" pozicije i "Travel limita"

Prilagodite atribute kontrolera kroz profile

Export APT, za PLC...

Kreirajte i simulirajte transportne sisteme (lifter, turntable

systems, friction, skillet and slat conveyors)

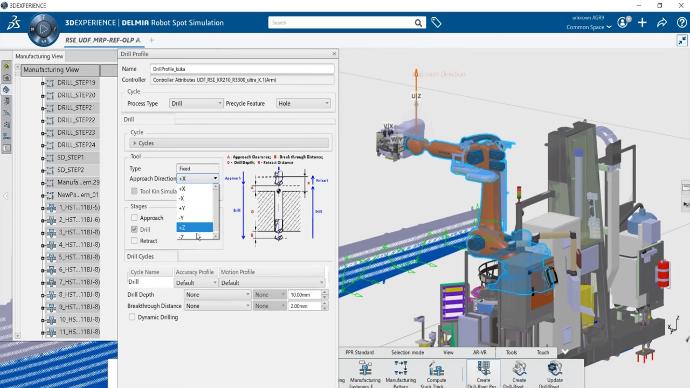

Mašinska obrada rezanjem pomoću robota

Da li imamo vašeg robota u Delmia 3DEXPERIENCE bazi?

Investirajte minimalno za maksimalne rezultate

ODABERITE ODGOVARAJUĆE DELMIA ROBOTICS MODULE PREMA VAŠIM POTREBAMA

3DEXPERIENCE okruženje za ceo tim i za sve vaše mašine i robote

Kao i kod drugih rešenja na 3DEXPERIENCE platformi, Delmia Robotic softverski paketi uređeni su po ulogama koju neko radno mesto obavlja:

- programeri za različite tipove robotskih operacija, procesa i industrija

- inženjeri koji upravljaju procesima robotskih operacija

U tom smislu, 3DEXPERIENCE platforma ne pruža samo bazične softverske alate da se generiše kod za putanju robota, već daje kompletno okruženje u kontekstu radnog mesta sa idejom da potpuno opremi radno mesto za sve što je potrebno.

Realna rešenja za realne uslove

U praksi to podrazumeva da je nekada potrebno editovati kodove, otvoriti originalnu dokumentaciju za više informacija, povući predviđene alate ili ispitati alternative u slučaju da primarni alat nije dostupan u trenutku kada posao treba da se završi. Takođe treba imati i menadžment robota, analizirati i optimizovati njihov rad, uklopiti robotske operacije u procese kontrole kvaliteta, itd.

Sve ove aktivnosti treba da imaju zaduženu osobu, utvrđene korake (ko šta može da radi, ko šta odobrava, ko je za šta odgovoran), kako bi roboti postigli punu operativnost i efikasnost i doneli profit.

Kupite samo ono što vam je zaista potrebno

Dodatna prednost ovakvog Delmia Robotics pristupa jeste to što korisnici mogu da odaberu šta im je konkretno potrebno u skladu sa njihovim proizvodima i procesima, pa se i "tehnički" Delmia Robotics alati dele u module prema tipu robotskih operacija (tačkasto ili lučno zavarivanje, mašinska obrada robotima, farbanje, itd).

To znači da ne morate kupiti kompletan paket sa svim uključenim modulima po visokoj ceni jer svejedno jedan robot nikad neće u određenom vremenskom intervalu obavljati sve funkcije već će imati nekoliko osnovnih primena, a najčešće samo jednu - onu gde obavlja svoj deo posla u širem kontekstu vaše proizvodnje.

10 modula/rola Delmia Robotics softvera

SVAKA ROLA SADRŽI 10 DO 50 APLIKACIJA DA OBAVI SVOJ POSAO EFIKASNO

Osnovne tehničke aplikacije za upravljanje robotima

DELMIA ROBOTICS APLIKACIJE U ROLAMA

Mfg Context Builder

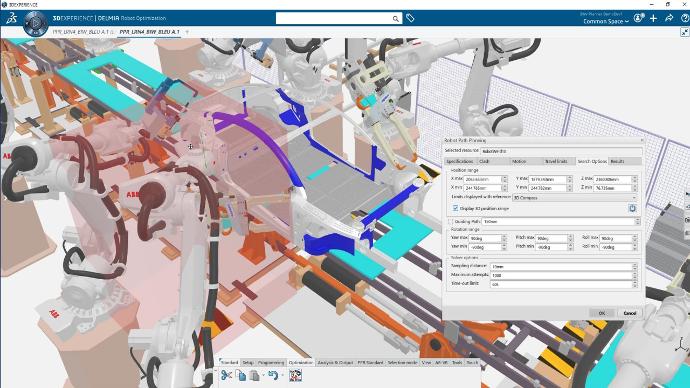

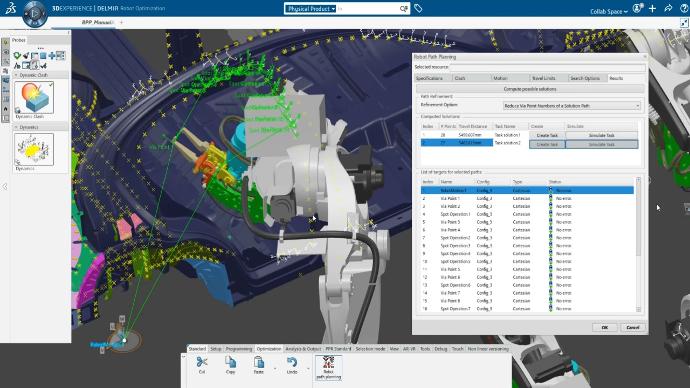

Robot Optimization

Robot Programming

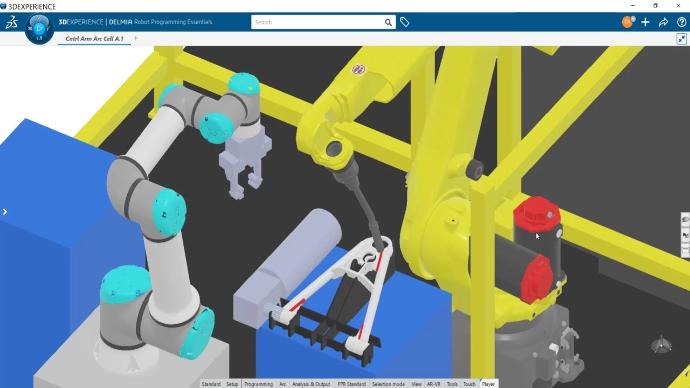

Robot Programming Essentials

Robot Simulation

Robot Spot Simulation

Robot Arc Simulation

Robot Virtual Commissioning

Robot Virtual Commissioning Review

Tool Analysis

Upravljanje procesima, komunikacija i timski rada

ENOVIA 3DEXPERIENCE APLIKACIJE U ROLAMA

Bookmark Editor

Change Execution

Collaborative IP Management (nije u svim rolama)

Collaborative Lifecycle

Data Setup

Design IP Classification

Exchange Management

Manufacturing Finder

Mfg Context Builder

Product Finder

Product Structure Design

Simulation Finder

System Finder

NAPOMENA: Neke Delmia Robotics role sadrže i CATIA CAD aplikacije kada je to neophodno da se pripremi i prati proizvodnja i kontrola kvaliteta.

Assembly Riveting System Programmer for Aerospace

Program, simulate, and validate complex Robot drilling and riveting systems in a 3D Virtual Factory context

- Simulate and validate complete drilling and riveting Robotic systems to eliminate costly crashes and optimize the production rate

- Deliver accurate, production-ready robot programs while keeping robots in production with offline robot programming

- Enable simultaneous engineering while offline to accelerate the start of production

- Fully simulate the complete workcell, including PLC control logic by performing virtual commissioning

DELMIA ROBOTICS APLIKACIJE

- Robot Optimization

- Robot Programming

- Robot Simulation

- Robot Spot Simulation

- Robot Virtual Commissioning

-

Tool Analysis

Assembly Robot Programmer

Program, simulate, and validate Robotic assembly systems in a 3D Virtual Factory context

- Simulate and validate complete robot spot welding and drill & riveting systems to eliminate costly crashes and optimize the production rate

-

Deliver accurate, production-ready programs while keeping robots in production with offline robot programming

- Enable simultaneous engineering offline to accelerate the start of production

DELMIA ROBOTICS APLIKACIJE

- Robot Programming

-

Robot Simulation

-

Robot Spot Simulation

- Tool Analysis

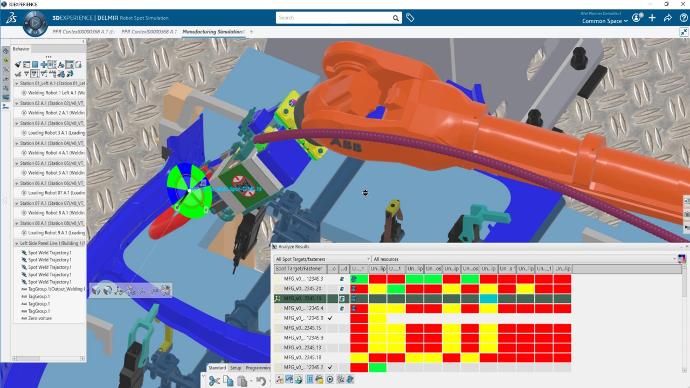

Body-in-White Robot Programmer

Define, validate and program Body-in-White robot systems offline in the Virtual Factory

- Simulate and validate complete robot spot welding and material handling systems to eliminate costly crashes

-

Deliver accurate, production-ready robot programs while keeping robots in production with offline robot programming

-

Enable simultaneous engineering while offline to accelerate the start of production

-

Fully simulate the complete workcell, including PLC control logic by performing virtual commissioning

DELMIA ROBOTICS APLIKACIJE

-

Mfg Context Builder

-

Robot Optimization

-

Robot Programming

- Robot Simulation

- Robot Spot Simulation

-

Robot Virtual Commissioning

-

Tool Analysis

Body-in-White Robotics Engineer

Validate and optimize the Body-in-White robotics processes and resources with Robotics simulation and validation in a Virtual Factory context

- Reduce engineering time and optimize the workload balance to increase the production rate

- Perform robot reachability studies to ensure planned fasteners are feasible early in the manufacturing engineering process

- Reduce tooling costs using automated tool analysis to help minimize the number of weld guns

DELMIA ROBOTICS APLIKACIJE

- Mfg Context Builder

-

Robot Optimization

-

Robot Simulation

- Robot Spot Simulation

-

Tool Analysis

Fabrication Robot Programmer

Define, validate and program robot arc welding and sealant deposition systems offline in the Virtual Factory

-

Simulate and validate complete welding, sealant deposition and handling robotics systems to eliminate costly crashes and optimize the production rate

- Deliver accurate, production-ready robot programs while keeping robots in production with offline robot programming

-

Enable simultaneous engineering offline to accelerate the start of production

DELMIA ROBOTICS APLIKACIJE

- Mfg Context Builder

- Robot Arc Simulation

- Robot Programming

-

Robot Simulation

Fabrication Robot Workcell Programmer for Industrial Equipment

Program, simulate, and validate Robotic fabrication systems in a 3D Virtual Factory context

- Simulate and validate complete robotic arc welding, gluing and sealant deposition systems to eliminate costly crashes and optimize the production rate

- Deliver accurate, production-ready robot programs while keeping robots in production with offline robot programming

- Fully simulate the complete workcell, including PLC control logic by performing virtual commissioning

DELMIA ROBOTICS APLIKACIJE

- Mfg Context Builder

- Robot Arc Simulation

-

Robot Optimization

-

Robot Programming

- Robot Simulation

-

Robot Virtual Commissioning

Robot Programmer

Build, Simulate, Validate and Program Industrial Robot workcells.

Provides robot programmers with a comprehensive and robust set of capabilities to help layout and program robotic systems more safely and efficiently. This new 3DEXPERIENCE Works role makes it easy to tackle the end-to-end manufacturing engineering process including layout, simulation, validation, calibration and offline robot programming information saved on the 3DEXPERIENCE Platform.

- Best for arc welding, adhesives, cutting, machine tending, pick & place applications

- Kinematics for end effectors, clamps & fixtures

- Workcell and plant layout capabilities

- Includes robot library & robot translators

- Offline programming in native robot language

-

Calibrate the robot workcell

DELMIA ROBOTICS APLIKACIJE

- Mfg Context Builder

-

Robot Programming Essentials

Robotics Virtual Commissioning Analyst

Execute virtual commissioning scenarios on a Manufacturing virtual twin with accurate simulations of Robots, equipment and sensors connected to a PLC program

- Create sensors, generate and transform parts for multicycle scenario on any Robotics role

- Enable virtual validation and correction of the PLC Program to accelerate the start of production

- Reduce costly downtime by leveraging the virtual twin to train operators and maintenance workers

- Forecast workcell cycle time by connecting the virtual robot to the RRS II Standard or any proprietary Virtual Robot Controller server

DELMIA ROBOTICS APLIKACIJE

- Mfg Context Builder

-

Robot Virtual Commissioning Review

Surface Robot Programmer

Define and validate offline program robotic finishing systems in the Virtual Factory

- Improve surface finish quality and save programming time by generating trajectories directly from the product geometry

- Keep robots in production longer via offline programming in the virtual factory

- Simulate new programs to minimize cycle time and avoid costly crashes

- Ensure accuracy of new programs by simulating the coverage of processes such as spray painting and shot peening

DELMIA ROBOTICS APLIKACIJE

- Mfg Context Builder

-

Robot Programming

- Robot Simulation

-

Robot Surface Simulation

Robotic Workcell Simulation Engineer

Design, simulate and validate robot handling systems in the Virtual Factory

- Help to ensure feasibility by designing and validating complete robotic handling systems before procuring expensive equipment

- Avoid costly collisions and minimize cycle time by simulating and optimizing robot programs

-

Simulate to validate the handling of new products before introducing into the production system

DELMIA ROBOTICS APLIKACIJE

- Mfg Context Builder

- Robot Simulation

NAPOMENA - 3D CAD CATIA APLIKACIJE

Ova rola ima preko 30 uključenih aplikacija koje povezuju CAD i PLM procese. Samo neke od dodatnih CAD specifičnih aplikaciju kojih nema u većini drugih rola u Delmia Robotics softveru jesu:

- 3D Layout for 3D Design

- 3D Annotation Experience

-

3D Printing

-

3D Templates Capture

-

Assembly Design

- Data Setup

-

Component Family Definition

-

Converter for IGES

-

Converter for STEP

-

Drafting

- Drafting Template Essentials

-

Generative Wireframe & Surface

- Material Definition

-

Product Structure Design

- Part Design Essentials

-

Quality Rules Reuse