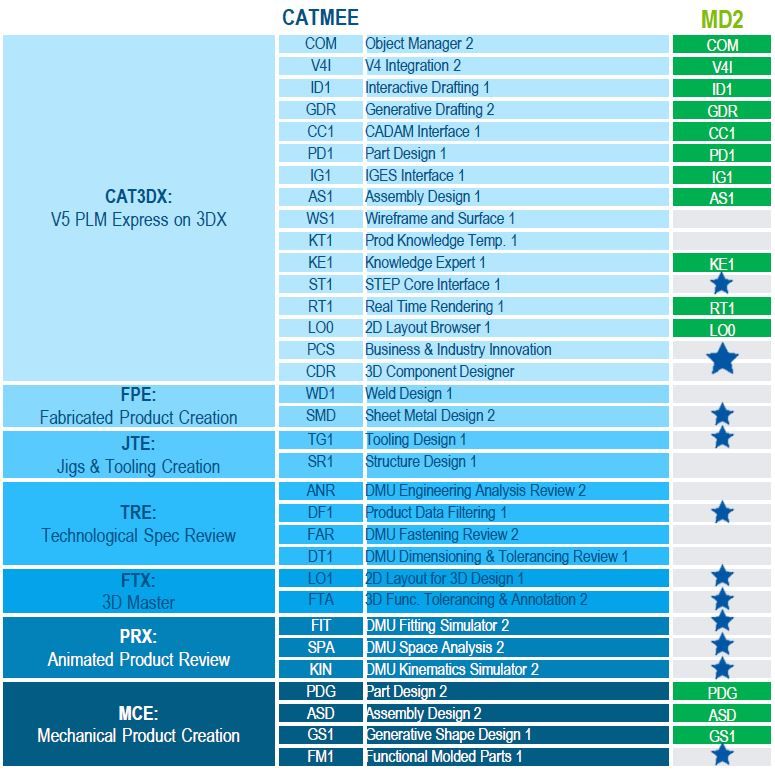

Matrix of standard CATIA mechanical configuration MD2 vs CATMEE

Ima u MD2 odn MCE(PDG) a nema u MD1 odn CAT (PD1) modulu a vezano je za PART DESIGN:

• Intersection Edge Fillet - Intersection against selected features

• Edge, Variable and Chordal Fillet - Blend Corner robustness

• Dynamic sectioning (Rad u kontekstu preseka)

• Sketcher un-perpendicular

• Stiffener : allows user to dramatically improve his productivity by selecting neutral profile (automatic generation and relimitation). This command is very differentiating in front of update (after modification)

• Thin Solid

• Catalog un-perpendicular holes

• Fillet preview available through a preview button

• Hold curve with spine

• Blend vertex fillet

• Multi Limiting

• Fillet reliability enhancement : local twist solving, geometrical quality of fillet extremities

• Draft with limiting surfaces

• Surface Sewing

• Sketch positioning : capability to position the sketch at the beginning of the design. It will allow the user to define the Absolute axis and will keep associativity with selected 3D elements. For instance, user will be able to specify that the origin of the sketch will be linked to the intersection of two 3D lines, the sketch support will be the plane through these 2 lines, the orientation will be fixed to one line. This capability will enhance sketcher update stability in front of strong modifications of the input. Sketcher integration in PowerCopy, UserFeature and Replace is reinforced.

• Auto-dimensioning of a sketch or of specified elements of sketch, support of Chain & stack methodologies

• Dynamic simulation of constraint variation applied on a sketch

• Predefined contours (oblong, hexagons, key hole...)

• Replace Part Design features' parents to increase productivity during modification by keeping associativity (available now for operand body under boolean operations)

• Horizontal modes

• "V" shaped tree

• Centered profile : This function allows users to create centered profiles, such as rectangles, oriented rectangles and parallelograms. The user selects one of these commands and, with the sketch toolbar, can choose the centered option. In classic mode, the profiles are created as usual. In centered mode, the user specifies a center point to start creating the profile.

• Set as Output : New capability to manage a single 2D geometrical element independently from the whole sketch.

• Sketch Wireframe or Surface Elements used in an exiting feature can be replaced by an other one

• Insert Body: Allowing to create a new body in an existing part tree

• Union trim, allowing to union several bodies while performing a trimming operation

• Union trim on re-limited faces allowing to save time during creation of complex part. It also drastically ease the use union trim operations

• Remove lump, allowing to remove several bodies while performing a trimming operation

• Capability to select a body in another part to operate (add/remove/assemble/trim/remove) it with the current feature

• Direct mouse-based manipulations on geometry to speed-up design, such as

• For Feature definition (Pad, Pocket, Shaft, Groove, Hole), limits of geometry can be stretched dynamically with the mouse or specified through the contextual menu

• For Hole definition, direct manipulations are available to move the hole position

• Preview during feature fillet, chamfer

• Deactivate / activate panel improves ergonomics and usability - Unify deactivate and delete commands regarding children (impacted elements) and aggregated elements. The behavior is more consistent for end user. It enables to Deactivate/Activate a complete branch of feature

- Save as Part - komanda ne postoji u PD1

Ima u MD2 odn MCE (ASD) a nema u MD1 odnosno CAT (AS1) modulu a vezano je za ASSEMBLY DESIGN:

Geometry "publication" for design in context

"To publish" a geometry means assigning a “label” to an existing geometry (e.g. assign the "roof" label to a geometry).

• A part can be designed in the context of a published geometry (pad UpTo “Roof” for instance). This is a powerful methodology to catch Part Design Intent in the Context of an assembly (Re-Use of contexts, Fit & Form concepts)

• An option allows to check that the user selects only "published" elements for design context

• Publication : ability to replace link by link in the "Define contextual links" pannel through 3D selection or specification tree selection

• Symmetrical sub-assemblies : ability to create a symmetrical sub-assembly to a user defined plan. The symmetrical sub-assembly is geometrically associative

• Assembly symmetry : associativity in structure (a component added in an Assembly Symmetry is associatively mirrored, user has the option to choose the component to mirror or not)

• Customized load of assemblies for better session memory management

The user specifies the parts to be loaded in the assembly before opening

• Intuitive specifications of assembly constraints and assistant for an automated parts placement

• Point/Curve + Point/Surface constraints : User can apply constraints between point and curve ; and between point and surface. This extends assembly constraints usability to better suit product design process.

• Point/Curve constraint: follow topological definition (C2 curves with C1 junctions)

• A new mode of constraint creation has been added allowing the user to create multiple constraints in one shot, gaining productivity

• User node for constraints : user can sort his constraints in the design tree to suit his logical organization. This improves readability of the tree and productivity through easier selection or operations on groups of identified constraints.

• Analysis of the degrees of freedom of a component, in order to quickly understand (graphically) how the component is constrained

• List non iso-constrained components

• Automatic positioning and constraints creation during motion using compass (SmartMove)

This command enables to:

manipulate a component using the compass and

automatically position it according to the flied-over geometry,

optionally create the corresponding constraints with orientation management

• Positioning assistant : This functionality is an enhancement of the existing "Smart move" command. The user select multiple components to be placed through snap or constraints and can manipulate them one by one in a dedicated 3D window, that improves productivity and ease of use.

• Insert with positioning / ability to fix part : A new push button is added to the panel, Fix Component. When pushed, it creates a fixity constraint on the currently positioned component, the one displayed in the panel viewer. The fixity constraint is created in mode Fix In Space. This is only available if no fixity constraint already exists on the component otherwise it is inactive dimmed. This enhancement enables the user of Assembly Positioning Assistant to fix the positioned component, by creating a fixity constraint.

Razlike u Catia V5 modulima