DELMIA CNC MACHINING

USING CNC MACHINES AND ROBOTS

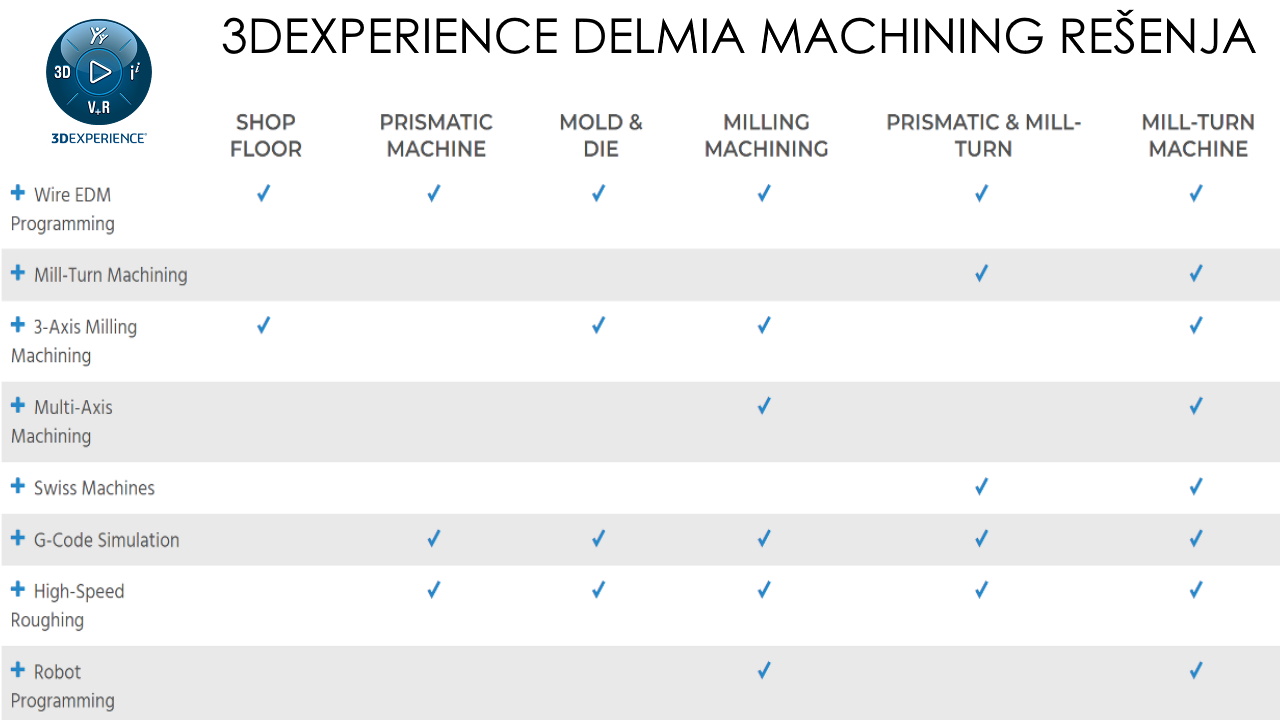

Formerly part of CATIA V5 software, the CNC machine programming segment is now part of the DELMIA product range within the new 3DEXPERIENCE platform.

Delmia machining modules

characteristics of the module for using CNC machines

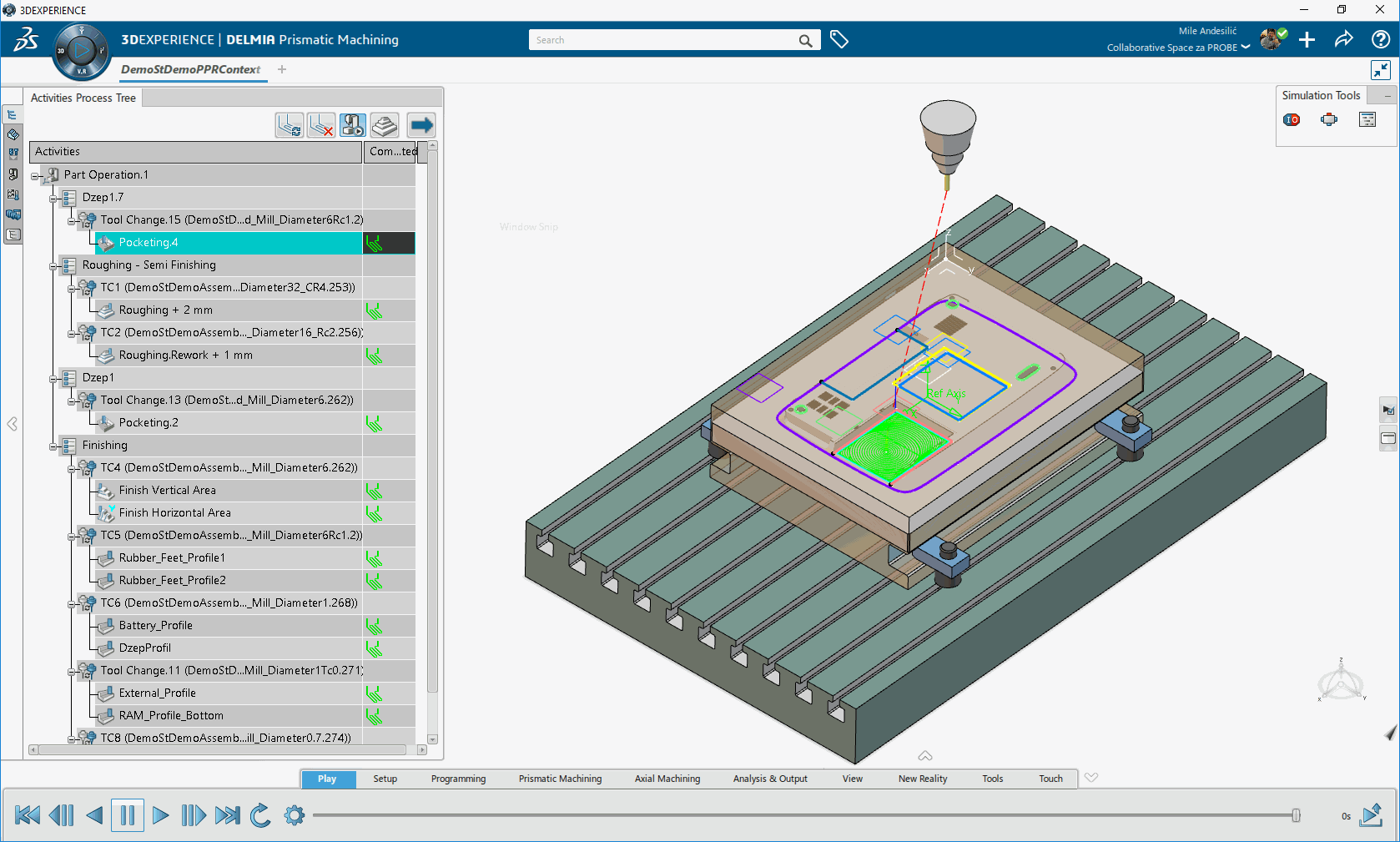

Delmia Prizmatic machining - NPM

Delmia 3DEXPERIENCE Prizmatic machining - NPM

The complete solution for programming 2.5-axis milling operations and 4-axis erosion

Prizmatic Machining key characteristics

Adaptive concentric milling

Strategies for hard metals and accelerations in everyday processing

4-axis pocketing

Supported and index 4-axis pocketing operations with user-controlled tool input angle for better cutting conditions. This operation supports both non-conical and non-cylindrical surfaces that go over 180°

Collision detection

Advanced collision detection between all machining factors (tools, brackets, clamping, and cutting accessories)

Tool and equipment center

Integration with web catalogs of tool and equipment manufacturers so you get the most accurate tool geometry possible with one click, with all modes and data from the manufacturer directly in the CAM software

Wire EDM - NPM

3DEXPERIENCE WIRE EDM

Programming of 2-axis and 4-axis erosimates

2 axis and 4 axis strategies and technologies for erosion management

Defining WireEDM Machines and Tools (Wire)

Pocketing operation

Path simulation

Delmia NC Shop Floor programmer

Prizmatično glodanje

Wire EDM

Generisanje APT and NC koda

Simulacija putanje i mašine

Baziran na 3DEXPERIENCE platformi automatski asocijativan sa Catia i SolidWorks 3D Modelima

NC Mold and Die Programmer

Built on the 3DEXPERIENCE® platform, NC Mold and Die Programmer immerses NC Programmers in a lifelike virtual workplace where they create, optimize, and validate milling programs. Programmers easily access current information for machining resources, NC programs, and part setup. NC Mold and Die Programmer also programs 2- and 4-axes wire EDM machines.

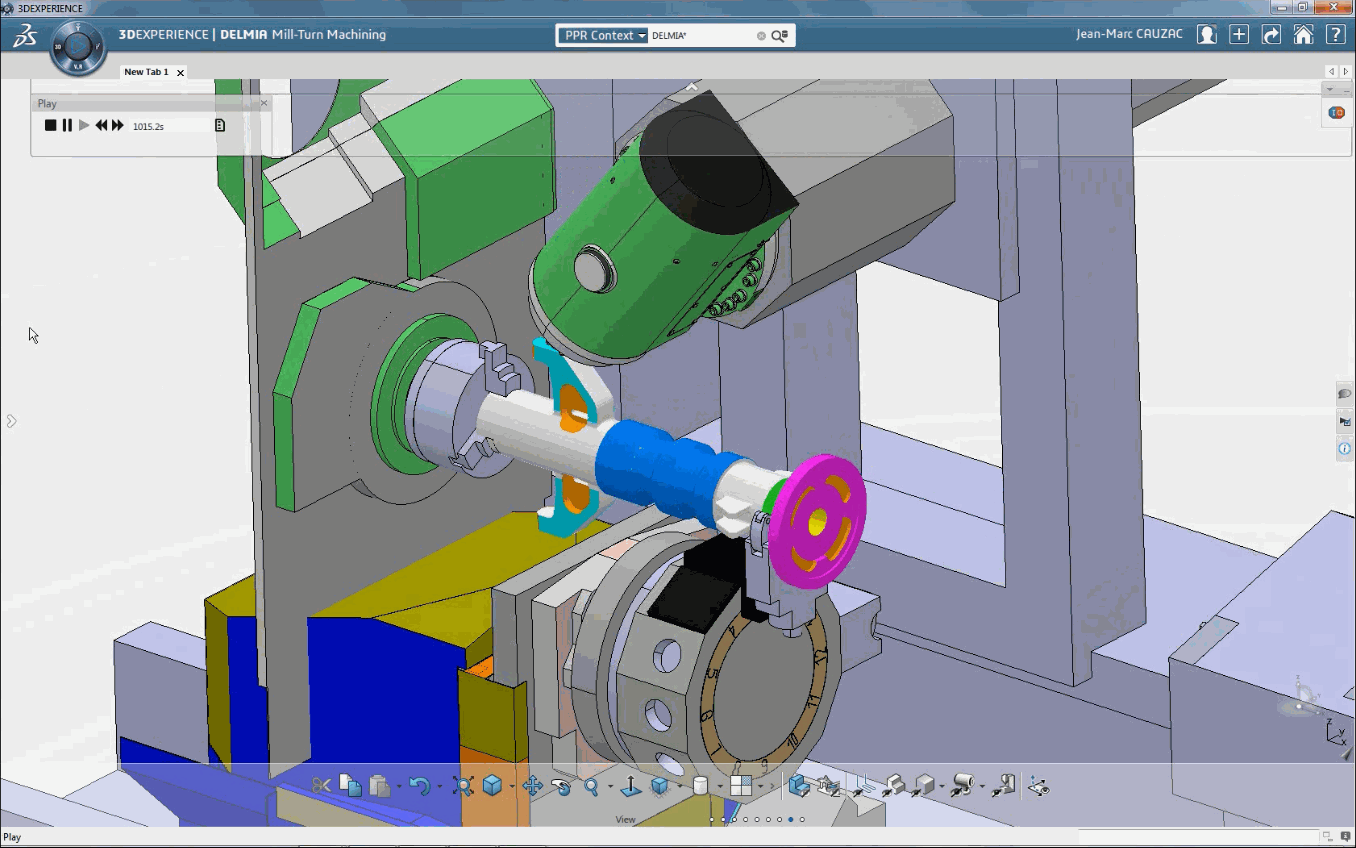

Prizmatic & Turning machining - NPT

Programming scraping operations

Add-on to Prizmatic machining - NPM

Creating and optimizingscraping operations

Synchronization of Mill-Turn operations

Generation of APT and NC codes

Automatic association with features from the Catia Part design module

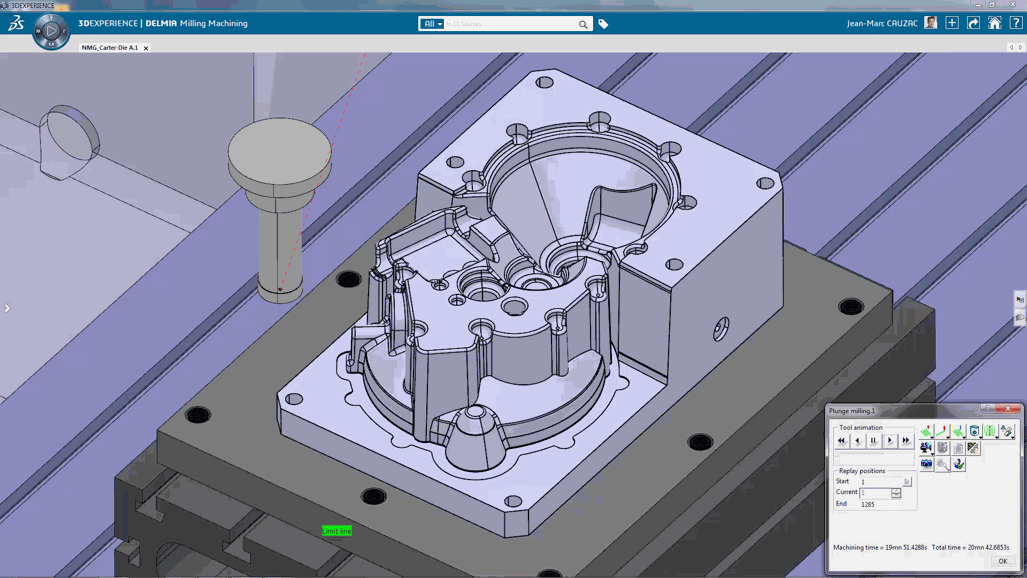

Milling machining - NMG

Program and simulate the operation of the 2.5-axis and 3-axis milling machines

Add-on to Prizmatic machining - NPM

Creating and optimizing strategies for rough and fine processing

Local or global conversion of 3-axis to 5-axis paths

Advanced surface treatment operations

Integrated machine simulation with material seizure simulation

Generation of APT and NC codes

Automatic association with features from the Catia Part design module

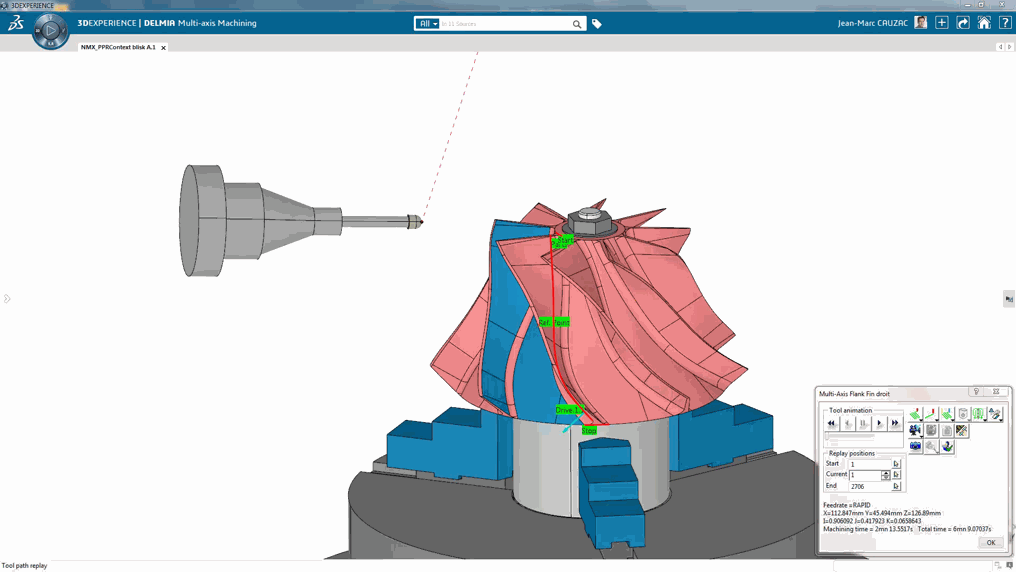

Multi-Axis Machining - NMX

Programming and simulation of advanced multi-axis milling strategies

Add-on to Prizmatic machining - NPM

Fantastic strategies for fine and rough processing

Integrated machine simulation along with material seizure simulation

Fast programming of multi-cavity parts

Generating APT, NC koda i 5-osni NURBS output

Automatic association with features from the Catia Part design module

Robot Milling - application for robot integration into machining

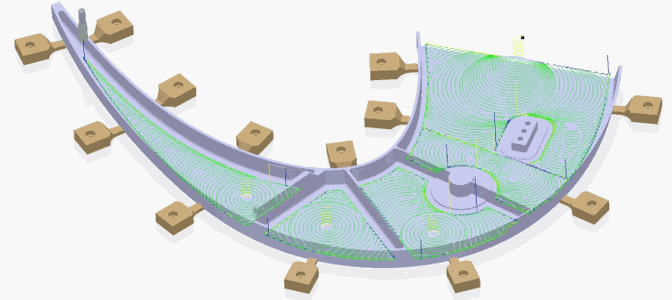

Adaptive concentric Milling

Special processing strategy

Unprecedented savings in rough processing! An integral part of every Delmia 3DEXPERIENCE CAM application. The trajectory automatically adapts to the geometry of the pocket, whether it is a closed or open pocket, with or without an island.

Check out the processing on the machine

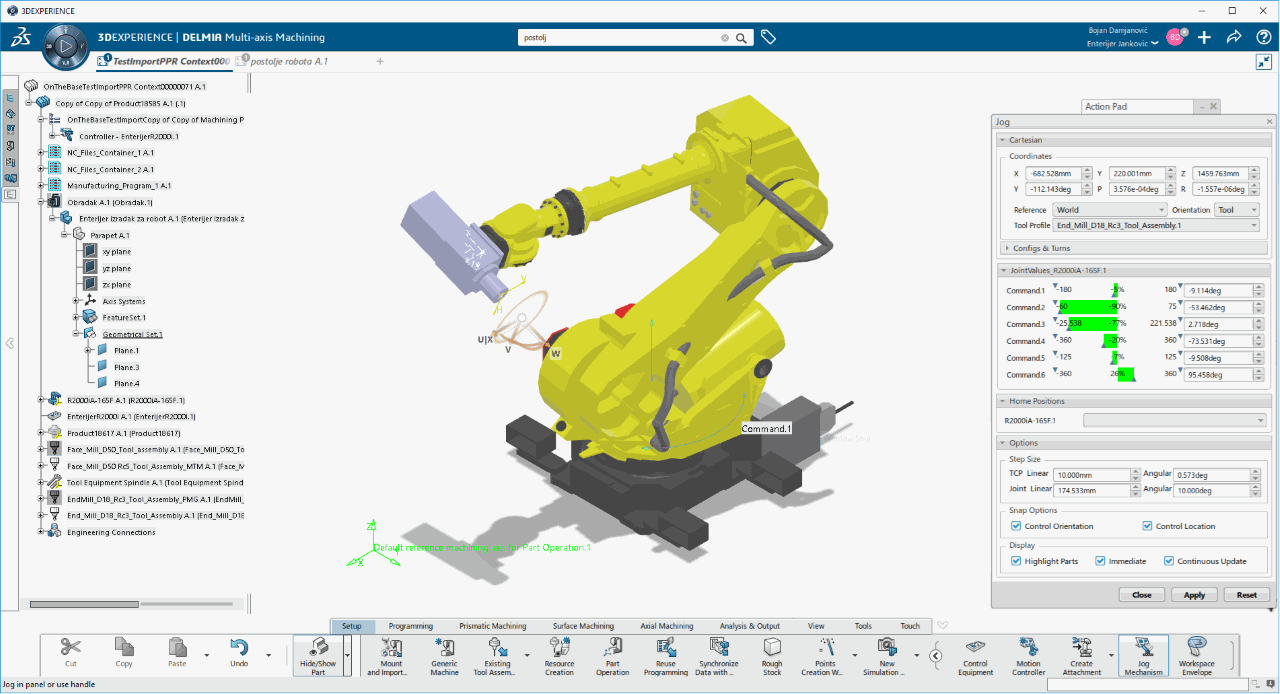

Robotic Multi-Axis Machining - NMX

6-axis CNC robotic machining - Delmia 3DExperience machining solution fully supports your robots without any special post-processors.

Robot Milling - application for robot integration into machining

Large Robot Base with predefined postprocessors

Special operations for manual robot instruction

Configurable base for accessories and attachments to the robot head

Generation of multiple kinds of codes for robots (TP, LS...)

Delmia Machining & Robotics - Virtual Twin of factory floor

Flexible manufacturing cell programming and simmulation

- any type of robot, controller or CNC machine

- machine utilisation planning

- simulation of every step

Pitanje/Odgovor

Kako postaviti i implementirati Delmia 3DEXPERIENCE CAM aplikacije?

Dostupno kao "Cloud" ili "On premise" instalacija. Pozovite naše CAM experte i posavetujte se o vašoj proizvodnji >> Contact

Koje CNC mašine mogu da se upravljaju Delmia CAM?

Delmia CAM applications can control all CNC machines with an infinite number of simultaneous axes.

Treba vam postprocesor da optimizujete rad CNC mašina?

Elementarni postprocesori se već nalaze u aplikaciji a Solfins tim ima bazu postprocesora a i razvija namenske postprocesore po meri kupca. Zatraži ponudu

Zatražite tehnološku konsultaciju i preporuku iz prakse?

Path and cycle time optimization is essential for efficient operation. Together we can find the best result for your machining.