Iskoristite SigmaNEST nesting rešenje da upravljate mašinama sa jednim ili više brenera.

SigmaNEST offers powerful features for oxyfuel cutting machines to improve efficiency, reduce scrap and produce clean parts. SigmaNEST supports all mission-critical feature requirements including heavy plate processing, complex bevel cutting, and multi-torch cutting. SigmaNEST optimizes cutting speed while maintaining edge quality in the plate as thick as 14 inches.

SigmaNEST knows heavy plate, and SigmaNEST X1 is the culmination of over 25 years of experience programming machines to cut some of the thickest material out there. We deliver exceptional edge quality, while reducing machine wear and lowering cutting times. SigmaNEST can help you compete into the future.

Zašto SigmaNEST za gasno rezanje?

- Leverage multi-torch nesting strategies optimized for automatic and manual torch spacing

- Achieve significant decreases in pierce quantities with chain cutting and bridge cutting technologies and extend torch tip life

- Pre-pierce on thicker material to reduce time in gas changes and also extend torch tip life

- Easy lead-in placement to reduce part distortion due to heat buildup

Glavne prednosti SigmaNEST rešenja za CNC gasno rezanje

CAD Integration

Automatic processing of flat pattern data from 3D CAD systems like SOLIDWORKS, Autodesk Inventor, PTC Creo, Siemens NX as well as IGES, DXF, DWG

Supports more CAD file formats for import than any other nesting solution

Advanced Auto Nesting

Improved production speed and material usage through chain, bridge, and common-line cutting

Maximum yield nesting

Common-line nesting

Pattern matching

Nest on sheet remnants

NC Programming

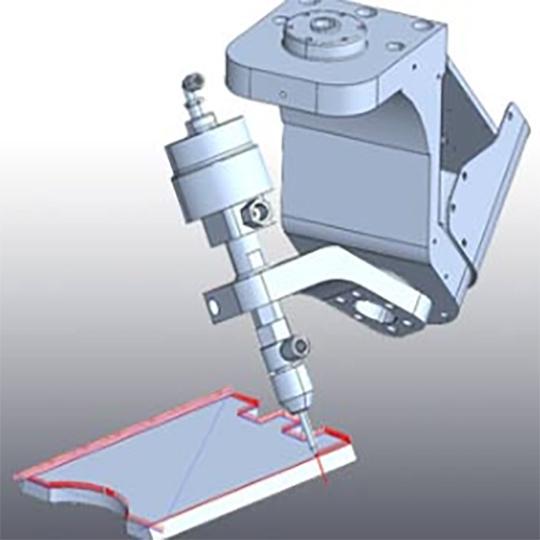

Eliminate drilling and reaming

Accelerate fabrication and profitability by eliminating secondary processes

Produce cleaner parts

Reduced taper

Improved cylindricity

BHQ™ Module

SigmaNEST BHQ™ improves on market-leading hole quality cutting strategies by offering both bolt-quality precision and optimization of taper, roundness, and machine runtime. Automatic lead-in lookup is based on hole size, material thickness, process type, and power.

CNC mašine za rezanje gasnim brenerom - SigmaNEST podržane mašine