Programirajte vaše mašine za obradu cevi i profila pomoću SigmaTUBE koji je integrisan sa SolidWorks softverom.

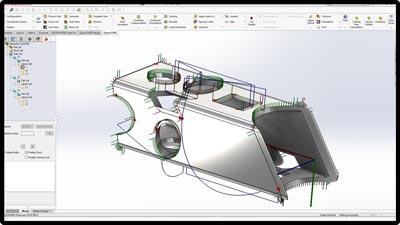

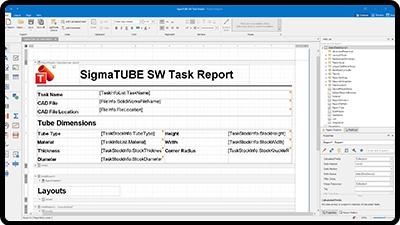

SigmaTUBE is a complete tube and pipe cutting software that operates seamlessly inside SOLIDWORKS. Custom modules help you optimize material usage and get the most out of your tube cutting machine. Supported machines include Mazak FabriGear, Trumpf, Bystronic, Amada and more.

Specijalizovani SigmaNEST moduli za cevi i profile

SigmaTUBE features include automatic separation by cross-section, instance count control from BOM, revision control, and automatic or manual leadin/leadout placement. You can also view machine-specific 3D cutting simulations and collision detections before sending your program to the machine.

SigmaTUBE funkcionalnosti

Tube recognition

Beam recognition

Automatic feature recognition

Rotary cutting

Sketch creation and wrapping

Feature suppression for cutting

Space frame and tube frame

Cutting technology database

SigmaTUBE prednosti

Complex programming made easy

Faster turnaround time for orders

Optimized material usage and machine performance

Empower your programmers to be more flexible and productive

No separate CAM system required

Automatically generate toolpath for solid part geometry

CNC mašine za sečenje i obradu cevi i profila - SigmaNEST podržane mašine