Zvanična Dassault Systemes referenca

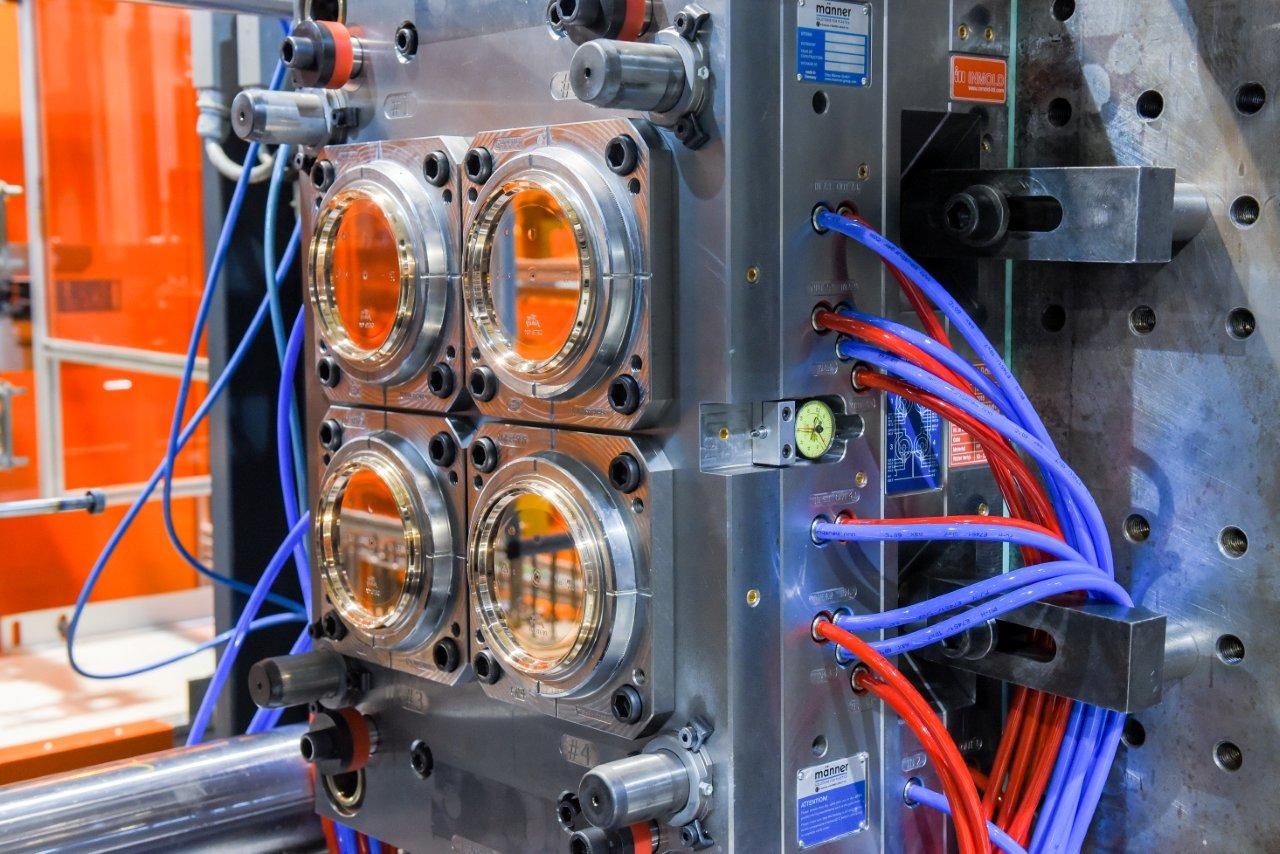

Inmold kao globalni primer primene savremenih tehnologija - najtanje pakovanje na svetu

Inmold je izabran od strane kompanije Dassault Systemes kao jedna od najuspešnijih implementacije 3DEXPERIENCE platforme:

Inmold Plast, Požega

Central Serbia

The leading molding factory complex in Serbia has a software portfolio based on Dassault Systemes solutions implemented by Solfins for various sectors and products:

- product desing

- molding tools design

- molding services

- IML robots design and manufacturing

New step for Solfins and Inmold partnership is 3DEXPERIENCE implementation for packaging sector.

Inmold was looking for a partner capable of providing:

- consulting and expertise

- full software solution

- software implementation

- employee traininngs

- technical support

- resourses for further software upgrades...

With Solfins solutions and implementation Inmold achieved:

- speed in development process

- product design confirmation before expensive prototypes and production

- reduced waste and assembly cycle times

- fast concept development

- short delivery cycles toward clients

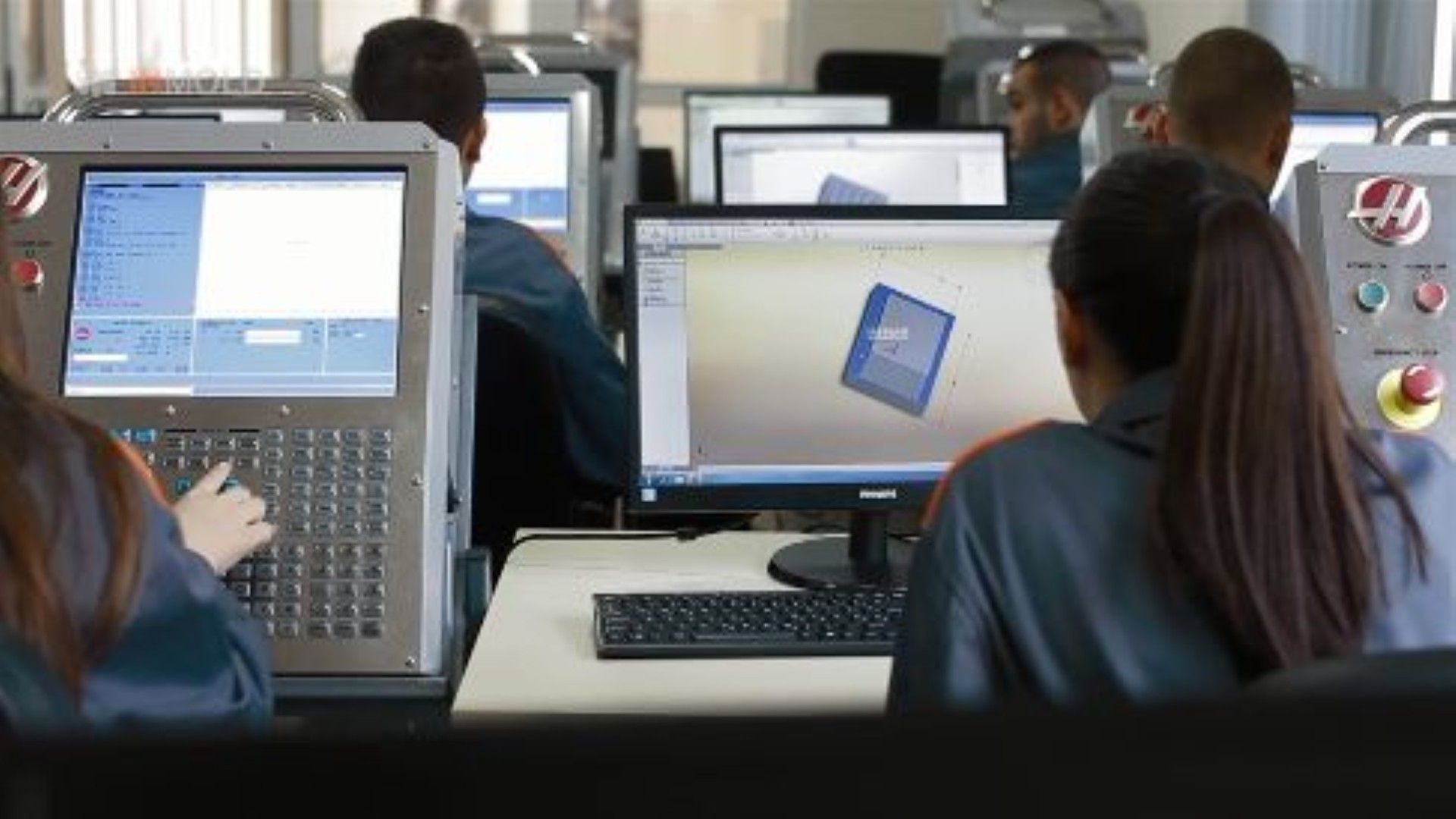

Continuous Education and Training

Scholarship partnership program for high school students from local community since 2011. for computing and mechatronics studies - Dassault Systemes software implemented in education process.

Seminars and training for employees organized with partners in factory presentation and traininngs hall.

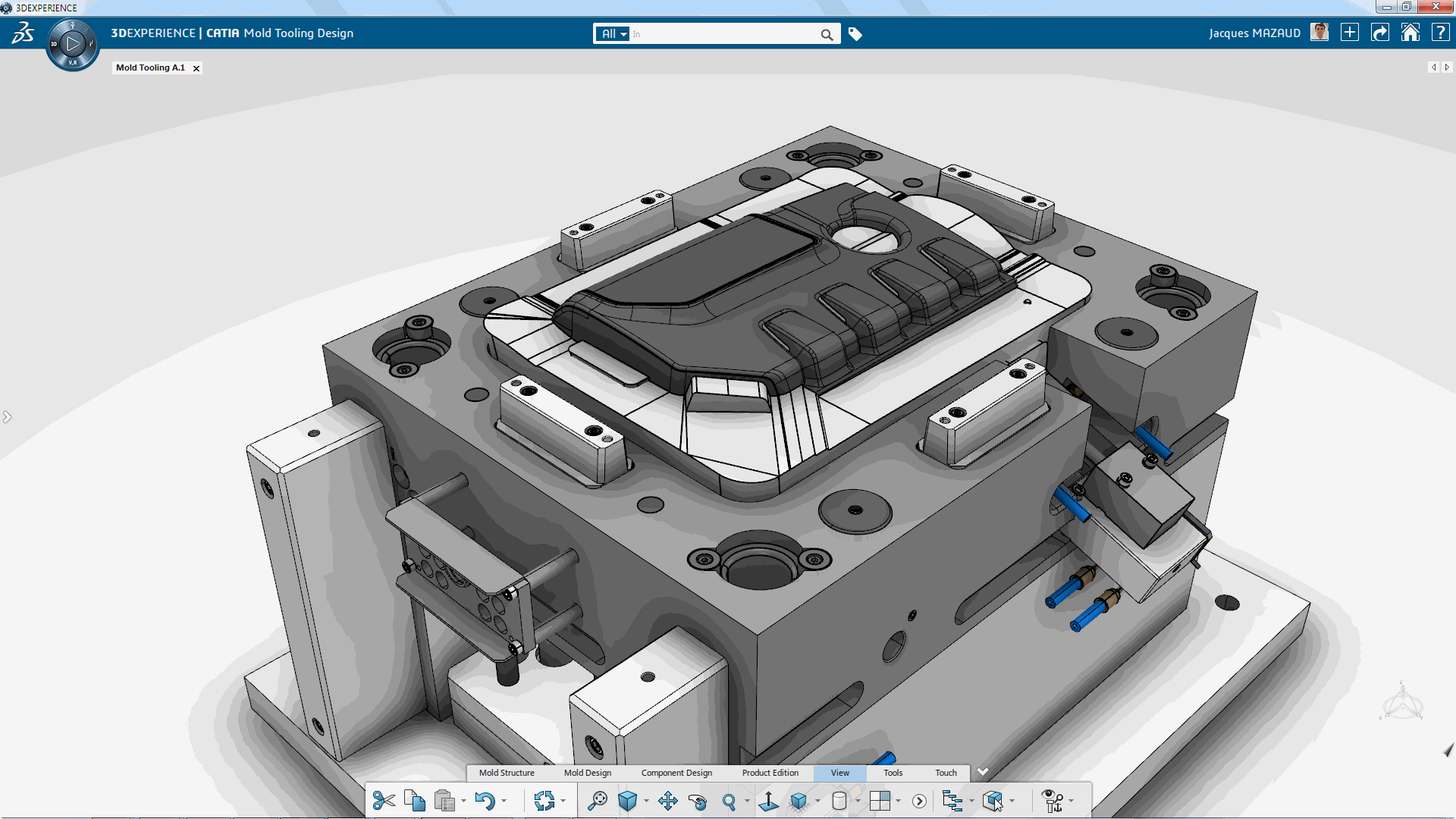

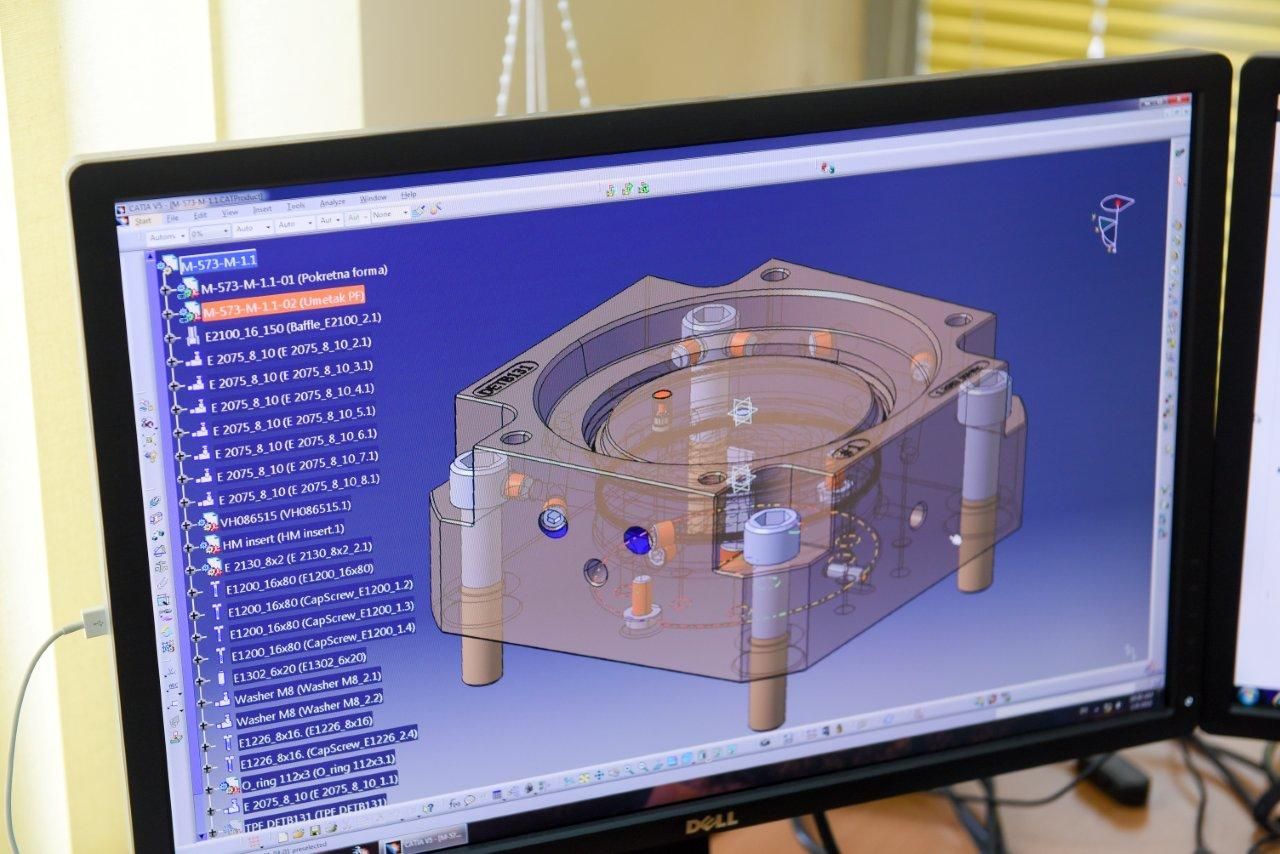

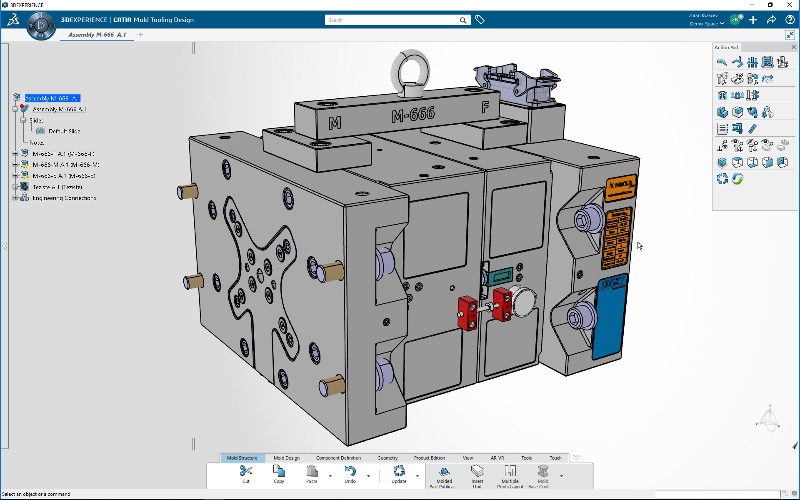

3DEXPERIENCE Implementation

In 2018 Solfins has begun with full 3DEXPERIENCE platform implementation in company Inmold Plast - packaging sector:

- project management

- team work and documentation management

- product change management

- issue management.

upravljanje projektima, timski rad i upravljanje dokumentacijom, menadžment izmenama i problemima (issue management).

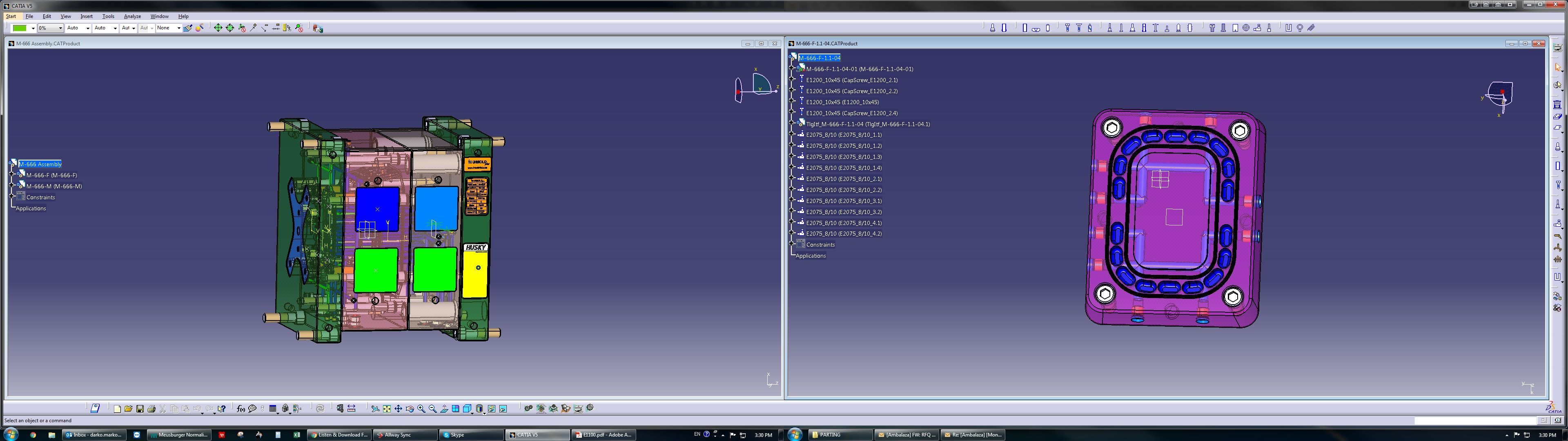

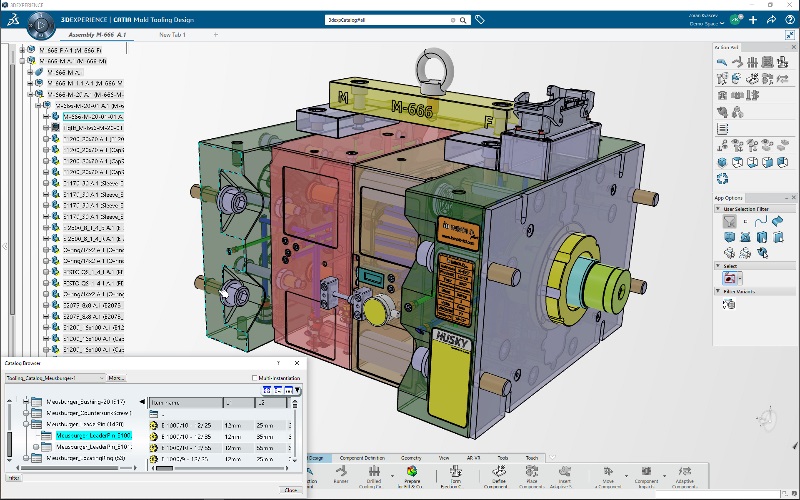

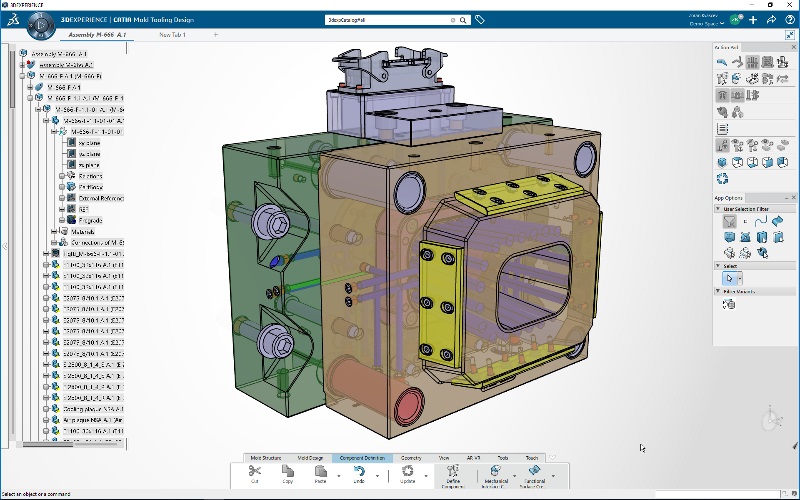

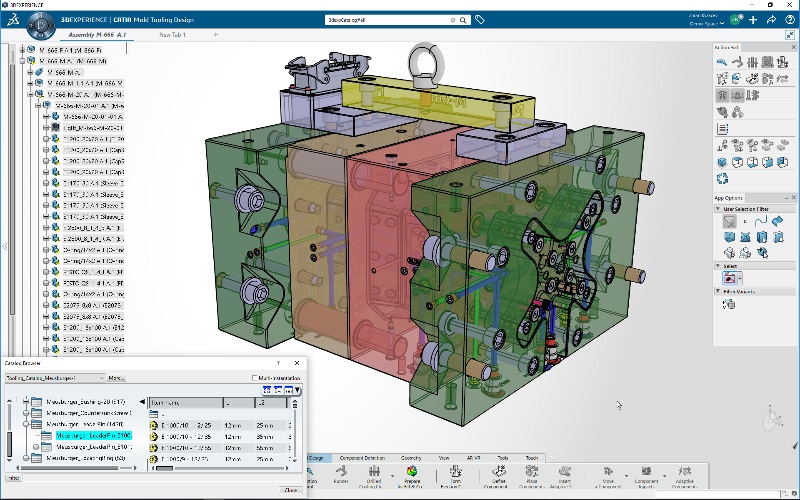

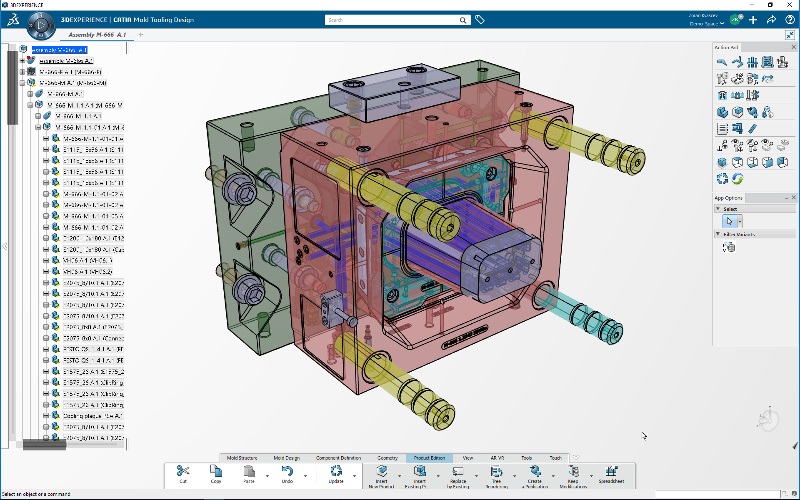

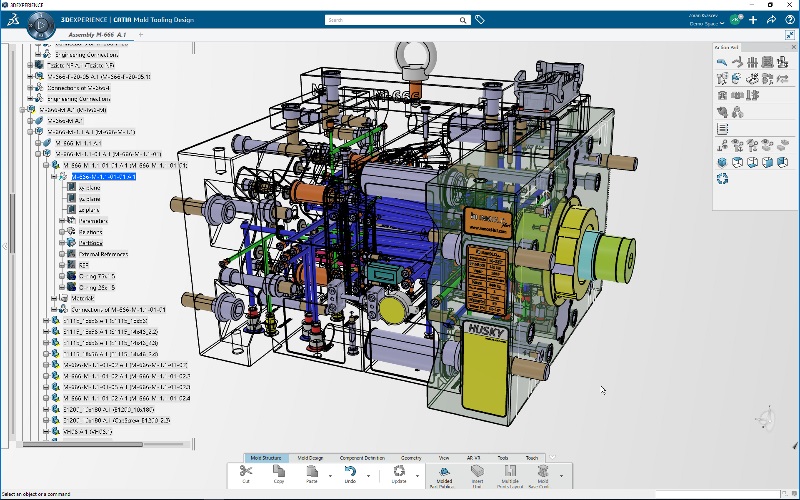

In addition, new CATIA 3DEXPERIENCE has been implemented for improves mold tool design process. brojna unapređenja u domenu konstrukcije alata i integraciju sa ERP sistemom.

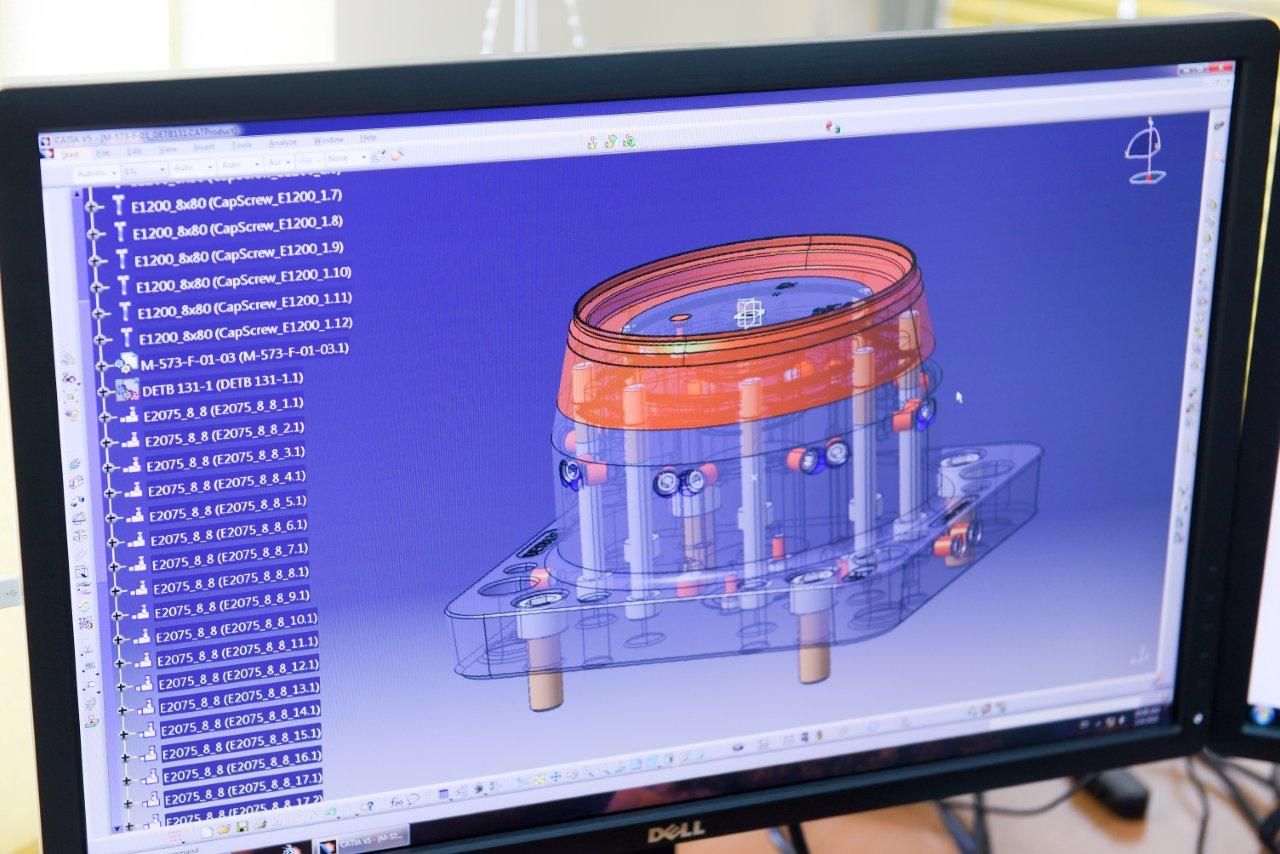

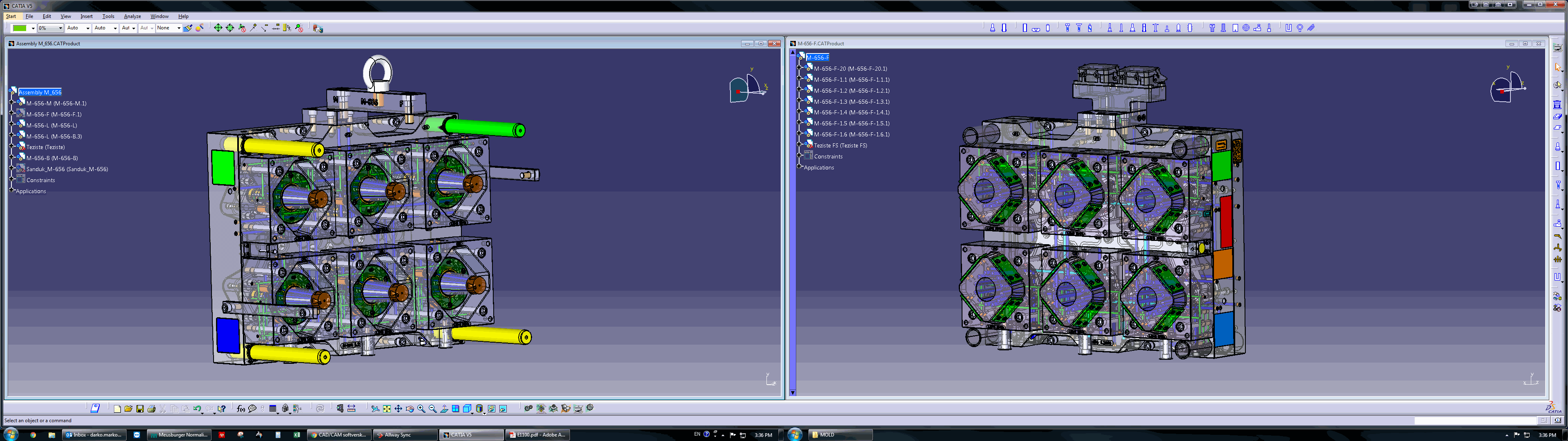

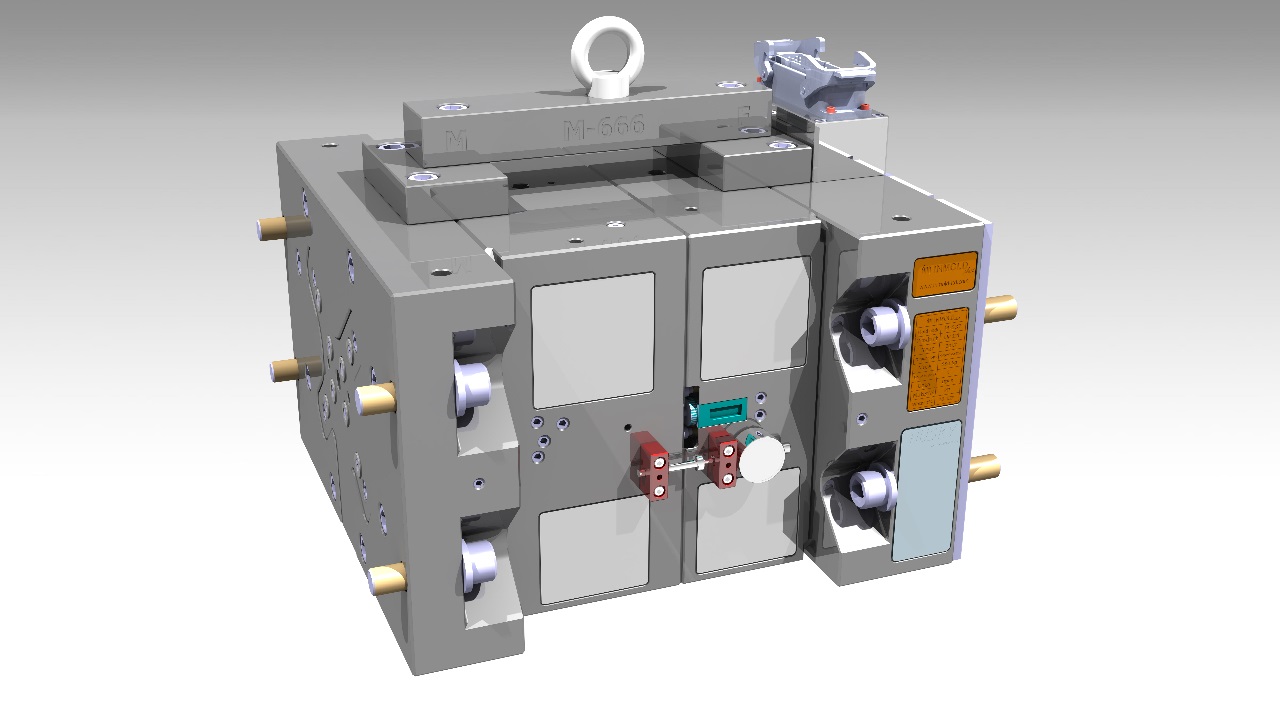

CATIA in Inmold Plast

Tool Design

Dosadašnja primena inovativnih tehnologija iz ponude kompanije Solfins (SolidWorks 3D CAD, Catia V5 3D CAD) i kontinuirana edukacija kadrova kompanije Inmold rezultovala je rastom kompanije i otvaranjem novih tržišta i poslovnih prilika.

Kompanija Solfins se zahvaljuje na ukazanom poverenju u ostvarenju ciljeva kompanije Inmold da svojim klijentima ponudi najbolju moguću uslugu i da se na taj način izdvoji od konkurencije.

Photo GALLERY:

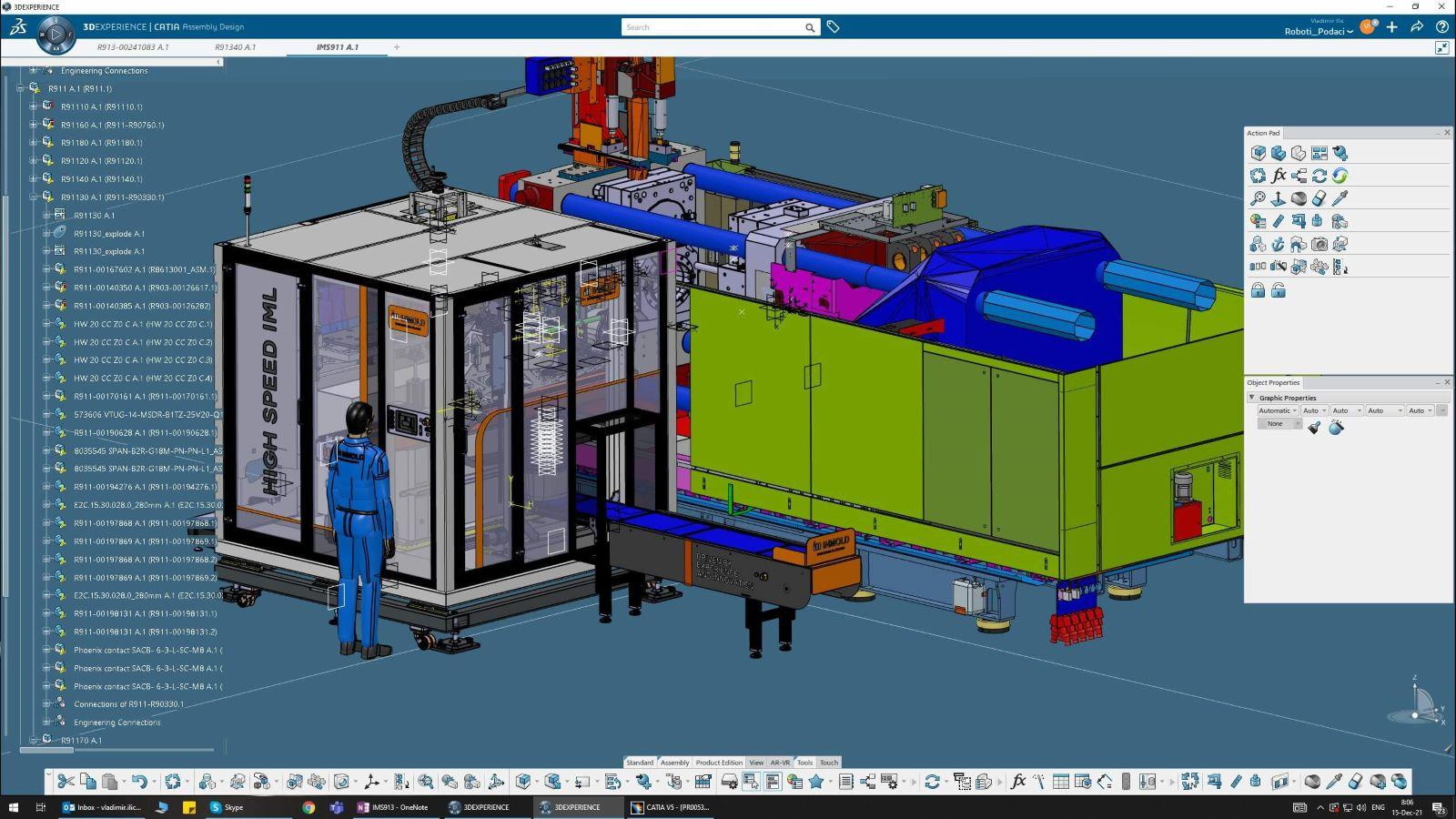

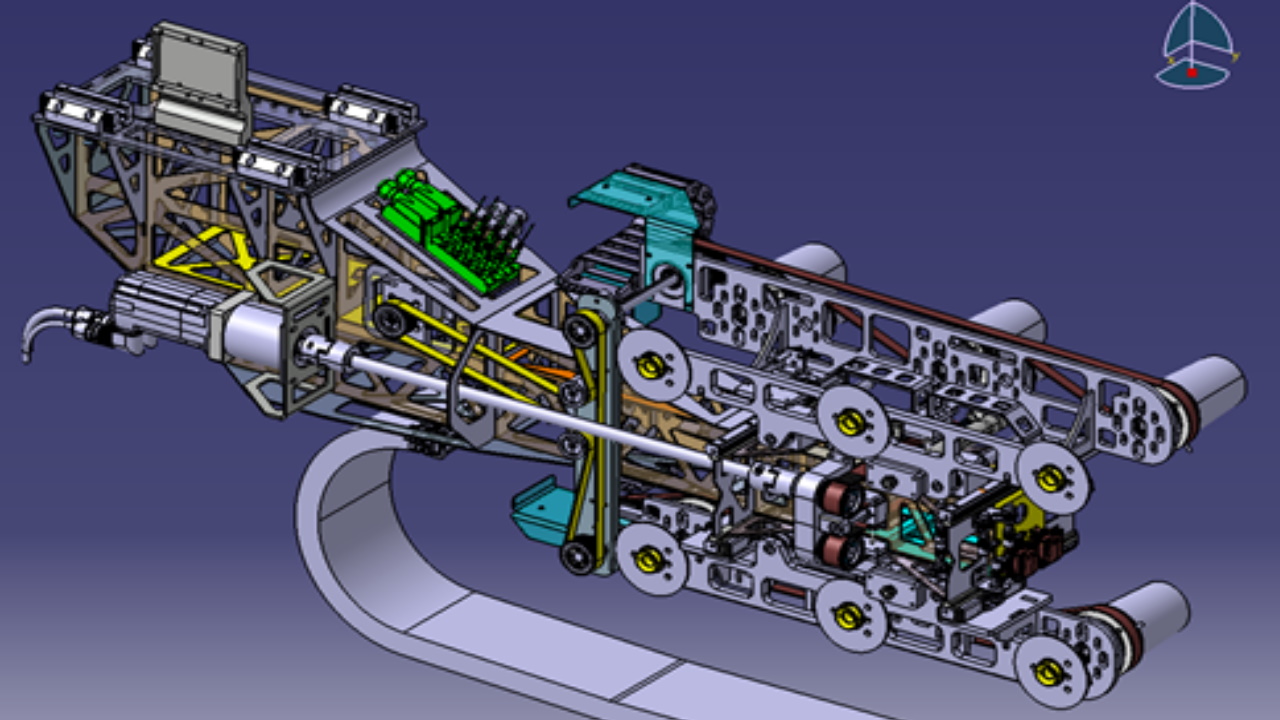

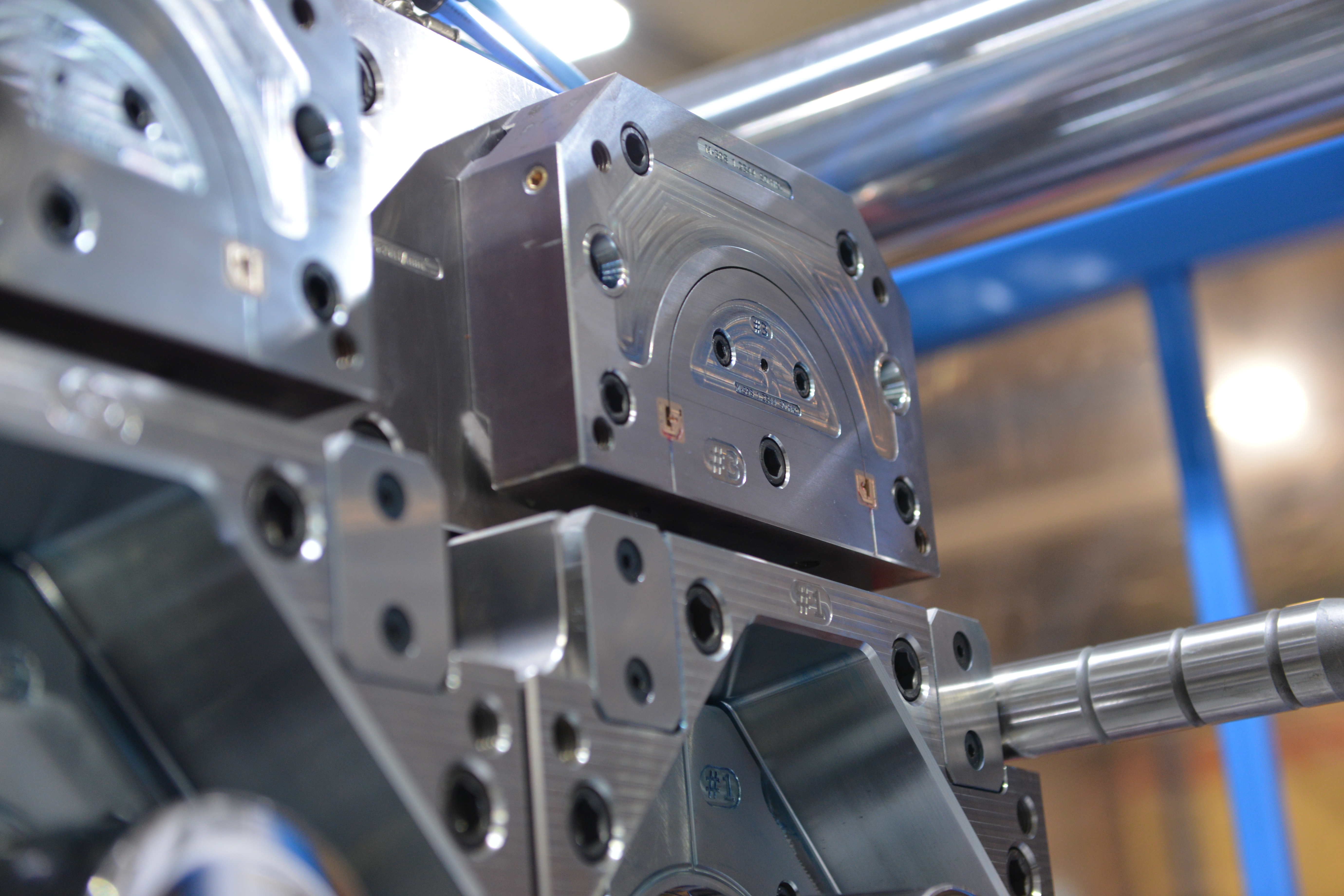

IML Robot

IML ROBOT

Saradnja inženjeringa Solfinsa i Inmolda

U želji da razvije efikasnije i pouzdanije mašine i robote za sopstvenu proizvodnju, Inmold je uposlio i iskustvo i kapacitete Solfins inženjeringa na veoma zanimljivom projektu optimizacije IML robota.

Za saradnju dva inženjerska tima, gde je jedan u Požegi a drugi u Beogradu, korišćena je 3DEXPERIENCE platforma sa simultanim pristupom za sve članove zajedničkog tima koji su bili direktno uključeni u ovaj projekat.

Contact Solfins Optimize your R&D and Manufacturing

Inmold plast, Požega